您想继续阅读英文文章还

是切换到中文?

是切换到中文?

THINK ALUMINIUM THINK AL CIRCLE

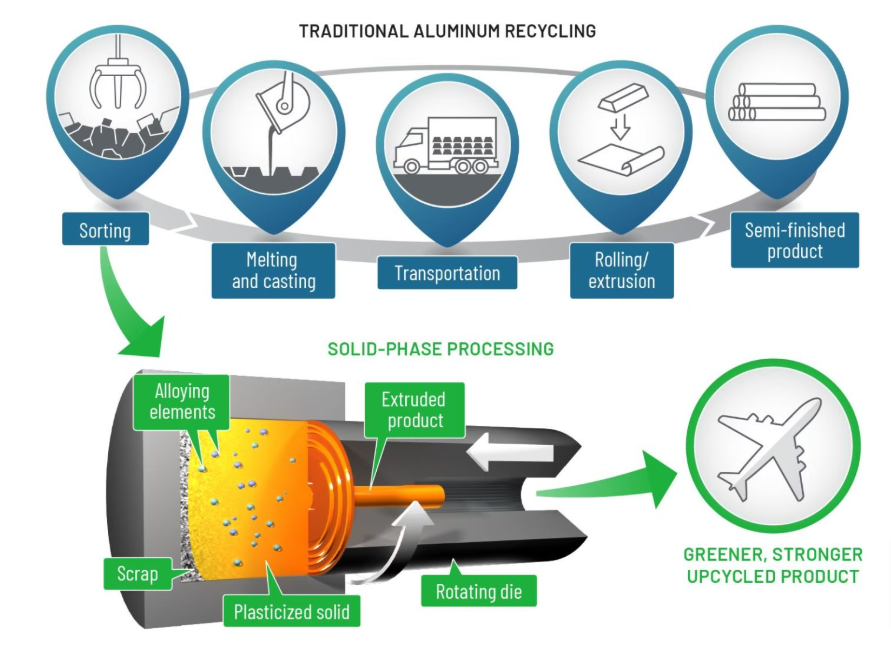

Researchers at the Department of Energy's Pacific Northwest National Laboratory (PNNL) have developed a groundbreaking method to directly transform and upgrade metal scrap into high-performance, high-value alloys using a technique called "solid-phase alloying." This innovative approach eliminates the need for conventional melting processes.

Source - PNNL website

Source - PNNL website

Use of ShAPE

The research team utilised a PNNL-patented technique known as Shear Assisted Processing and Extrusion (ShAPE) to achieve these results. Importantly, the researchers emphasised that these findings are likely replicable with other solid-phase manufacturing techniques.

The ShAPE process utilises a high-speed rotating die to generate friction and heat, transforming the coarse starting materials into a uniform alloy with properties identical to newly manufactured aluminium wrought products. This solid-phase approach significantly lowers energy consumption by eliminating the need for energy-intensive bulk melting. When combined with the use of low-cost scrap-based feedstocks, it offers a substantial reduction in manufacturing costs.

For consumers, this innovation translates into recycled aluminium products that are more durable, perform better and are more affordable—whether used in vehicles, construction materials, or household appliances.

"Our ability to upcycle scrap is exciting, but the thing that excites me the most about this research is that solid phase alloying is not just limited to aluminium alloys and junk feedstocks. Solid phase alloying is theoretically applicable to any metal combination that you can imagine, and the fact that manufacturing occurs wholly in the solid state means you can begin to consider totally new alloys that we've not been able to make before," added Cindy Powell, the chief science and technology officer for energy and environment at PNNL and a co-author of this study.

Image Source- PNNL website

Image Source- PNNL website

The study

The study, recently published in Nature Communications, reveals that scrap aluminium from industrial waste streams can be upcycled into high-performance metal alloys. Remarkably, the resulting aluminium matches the quality and performance of materials produced from primary aluminium. This breakthrough offers a cost-effective pathway for introducing more premium recycled metal products to the market.

"The novelty of our work here is that by adding a precise amount of metal elements into the mix with aluminium chips as a precursor, you can actually transform it from a low-cost waste to a high-cost product. We do this in just a single step, where everything is alloyed in five minutes or less," said Xiao Li, a PNNL materials scientist and lead author of the research study.

Converting industrial waste into high-performance aluminium alloys improves material properties and advances environmental sustainability. The innovative solid-phase alloying process rapidly transforms aluminium scrap mixed with copper, zinc, and magnesium into precisely engineered high-strength aluminium alloys within minutes—far faster than the days typically required using conventional methods like melting, casting, and extrusion.

Analysing the internal structure of materials recycled

The scientific team employed mechanical testing and advanced imaging techniques to analyse the internal structure of materials upcycled through solid-phase alloying. Their findings revealed that the ShAPE process imparts a distinctive nanostructure at the atomic level. Specifically, atomic-scale features known as Guinier-Preston zones form within the alloy during the process, enhancing the alloy's strength.

Compared to conventional recycled aluminium, the ShAPE upcycled alloy is 200 per cent stronger and exhibits significantly higher ultimate tensile strength. These improved properties can deliver longer-lasting, higher-performing products for consumers.

The solid-phase alloying process holds the potential for producing custom metal wire alloys tailored for a range of 3D printing technologies. For instance, it could support wire arc additive manufacturing (WAAM), a technique used to 3D print or repair metal components.

The research was funded by the Laboratory Directed Research and Development program at PNNL as part of the Solid Phase Processing Science Initiative. Key contributors to the study included PNNL researchers Tianhao Wang, Zehao Li, Tingkun Liu, Xiang Wang, Arun Devaraj, Cindy Powell, and Jorge F. dos Santos.

Responses