您想继续阅读英文文章还

是切换到中文?

是切换到中文?

THINK ALUMINIUM THINK AL CIRCLE

The Plansee Group, based in Reutte, Austria, initiated an ambitious project beginning in the spring of 2022. The project involves collaboration with Trimet, an aluminium manufacturer headquartered in Essen, Germany, as well as Arctus, a technology enterprise from Iceland, and Saarland University. The primary objective of this joint effort is to scale up a novel production method that eradicates the necessity of carbon in the aluminium manufacturing process. By replacing carbon dioxide with oxygen as a byproduct, this innovative approach significantly reduces the carbon footprint associated with aluminium production.

Plansee High-Performance Materials specializes in the manufacturing of components from molybdenum and tungsten. Whether in the semiconductor industry, consumer electronics, medical technology, or high-temperature furnaces, their refractory metals and composites come into play when regular metals reach their limits. As an innovation partner with its customers, they develop sustainable solutions for the high-tech world and continually push the boundaries of what is technologically feasible.

The global production of aluminium has reached an astonishing level. However, as demand continues to rise, so does the energy-intensive nature of its manufacturing process. This presents a dual challenge: not only does the smelting process necessitate significant energy consumption, primarily sourced from coal-fired power plants, but it also leads to a notable surge in CO2 emissions. The production process involves the combustion of carbon, releasing carbon dioxide into the atmosphere. As a result, approximately 100 million tonnes of CO2 equivalents are generated annually worldwide.

Trimet, in collaboration with Arctus, has pioneered a groundbreaking advancement in traditional aluminium production. The conventional electrolytic smelting process, known as the Hall-Héroult process, involves the reduction of aluminium oxide to aluminium metal using carbon electrodes, resulting in carbon dioxide emission as the carbon electrodes burn. However, the innovative process developed by Trimet and Arctus replaces the carbon electrodes with inert cathode material within the electrolytic cell. This significant development offers a crucial advantage by eliminating carbon electrodes, releasing oxygen instead of CO2 during the electrolysis. This breakthrough enables the production of lightweight aluminium without directly generating CO2 emissions, thus making a substantial contribution to more sustainable manufacturing practices.

Plansee's research project has set out to make this technological innovation commercially viable, spanning from laboratory-scale and small industrial cells to mass production. Additionally, the project aims to develop a superior material that can effectively replace carbon electrodes.

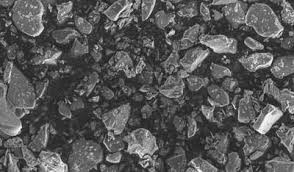

Plansee, a company known for producing TiB2 sputtering targets for tool coating, has identified titanium-diboride (TiB2) as a promising material due to its exceptional hardness, excellent oxidation resistance, and non-reactivity with aluminium. To meet the requirements of a new application, Plansee aims to adapt TiB2 by optimizing its corrosion properties in conjunction with an aluminium electrolyte.

Additionally, they seek to enhance its oxidation resistance for the upper section of the electrodes, which is exposed to high temperatures in the air. Furthermore, Plansee is leveraging its knowledge to develop a technique for connecting TiB2 cathodes to copper electrical connections, ensuring an efficient power supply.

Peter Polcik, the Product Development Manager at Plansee Composite Materials in Lechbruck, said, “Our research team is working on the project with great enthusiasm. As an innovation partner, we aim to guarantee the supply of optimised TiB2 cathodes to create electrolytic cells for manufacturing aluminium and thus significantly contribute to reducing Trimet’s CO2 footprint.”

Responses