Potash Ridge Corporation, a leading producer of potassium sulphate in North America has announced an update to the independent NI 43-101 Prefeasibility Technical Report for its Blawn Mountain Project dated January 18, 2017.

PFS indicates the production of 232,000 tons per year of potassium sulphate (SOP) together with sulphuric acid from 153.3 million tons of proven alunite reserves. The alumina-rich material was assumed to go into tailings.

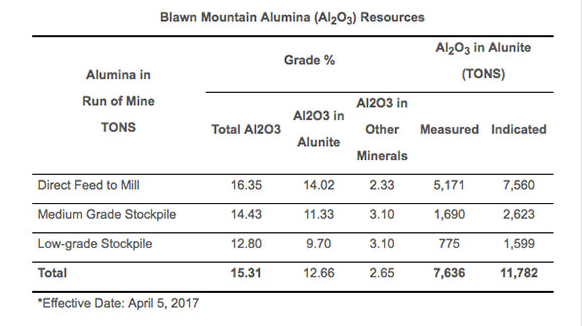

The PFS confirms the availability of alumina resources from alunite contained in the tailings and based on the PFS, Blawn Mountain alunite ore contains 19.4 million tons of measured and indicated alumina Resources.

According to a United States Geological Survey report, processed alumina was sold for US$410 per ton in 2015.

Till the time an economic recovery method is not established, alumina contained in the alunite ore would not be considered a Reserve. The table shows the measured and indicated alumina resources in the alunite ore that will be used to produce SOP and sulphuric acid. It does not include alumina contained in non-alunite material.

The potential applications for the alumina-rich residue material include its use as a binding agent in the production of cement, a raw material for aluminium and other industrial applications. Commercial discussions are underway to determine the optimal product mix. Based on the mine plan in the PFS, 19.4 million tons of pure alumina will be recovered in the tailings over the 46-year project life.

{googleAdsense}

Additional metallurgical testing will be done according to PFS recommendations, to determine the most economic means to extract alumina from alunite.

“Blawn Mountain is already a world-class SOP fertilizer project, with a long project life and very low operating costs," said, the Corporation's CEO. "The realization of market demand for the alumina contained in our tailings provides tremendous value upside potential and diversity to our revenue stream."

Responses