A surge of aluminium auto body scrap is expected to hit salvage yards over the next decade as aluminium-intensive vehicles, such as Ford’s F-150 truck series introduced in 2015, reach the end of their life cycles.

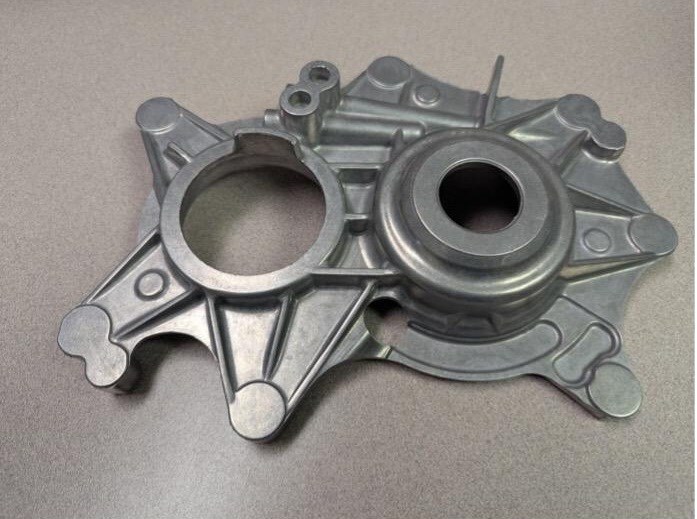

Image source: Oak Ridge National Laboratory

By the early 2030s, this could amount to as much as 350,000 tonnes annually in North America. Much of this material, however, is considered too impure for high-value automotive applications and is often downcycled into low-grade castings or exported.

Researchers at the Department of Energy’s Oak Ridge National Laboratory (ORNL) have developed an alloy they say could change that equation. Called RidgeAlloy, the material transforms low-value scrap into high-quality feedstock for critical automotive components, creating what could become a resilient, domestic supply chain for structural vehicle parts.

Turning scrap into structural components

DOE has designated aluminium a critical material for energy technologies that produce, transmit, store, and conserve energy. RidgeAlloy supports this designation by enabling post-consumer scrap to be recast into alloys with the strength, ductility, corrosion resistance, and crashworthiness needed for automotive structures.

ORNL’s Light Metals Core Program director Allen Haynes said, “The team advanced from a paper concept to a successful, full-scale part demonstration of a new alloy in only 15 months. That’s an unheard-of pace of innovation in developing complex structural alloys.”

The innovation addresses a long-standing problem: impurities, especially iron, that enter auto scrap during shredding and make the chemistry too unpredictable for structural alloys. As a result, most lightweight automotive parts today rely on primary aluminium, which is energy-intensive to produce and largely imported.

“You can repurpose post-consumer aluminium into something non-structural like engine blocks,” said Alex Plotkowski, ORNL group leader of Computational Coupled Physics. “But it won’t have the properties needed for higher value, structurally sound body applications.”

Science and technology behind RidgeAlloy

The ORNL team applied high-throughput computing, running over two million calculations to predict alloy compositions capable of tolerating impurities while still delivering performance. Materials characterisation and neutron diffraction at ORNL’s Spallation Neutron Source gave researchers unique insights into how alloy structures behave under different impurity levels.

“Using remelted scrap instead of primary aluminium is estimated to result in up to 95 per cent reduction in the energy needed for processing a part,” said Amit Shyam, leader of ORNL’s Alloy Behavior and Design Group.

The new alloy — made from aluminium, magnesium, silicon, iron and manganese — was tested using recycled auto body sheet scrap. PSW Group’s Trialco Aluminium in Chicago produced recycled ingots tailored to RidgeAlloy’s specifications. These were cast into automotive parts at Falcon Lakeside Manufacturing in Michigan using high-pressure die casting.

“The part we chose was medium-sized and moderately complex,” Plotkowski noted. “The ultimate goal is to eventually cast larger parts, perhaps even automotive giga-castings, but this is the first step.”

From laboratory to real-world impact

The demonstration confirmed that RidgeAlloy delivers the combination of strength, ductility and corrosion resistance needed for structural castings such as underbodies and frame components. By the early 2030s, researchers believe RidgeAlloy could enable recycled structural castings at volumes equal to half of US annual primary aluminium production, reducing energy use, cutting costs, and strengthening domestic supply chains.

“RidgeAlloy offers the first technology capable of recapturing the value of a fast-approaching and historically massive wave of domestic, high-quality recycled automotive aluminum sheet alloys,” Haynes said. “That’s the big picture supply chain impact our team aimed for.”

The technology could also extend beyond automotive into sectors such as aerospace, industrial machinery, agricultural equipment, off-road vehicles, and marine applications.

Collaboration and support

The RidgeAlloy project brought together a team of ORNL researchers including Alex Plotkowski, Amit Shyam, Allen Haynes, Sunyong Kwon, Ying Yang, Sumit Bahl, Nick Richter, Severine Cambier, Alice Perrin and Gerry Knapp. Funding and programme support came from the DOE’s Office of Energy Efficiency and Renewable Energy through the Vehicle Technologies Office Lightweight Metals Core Program.

UT-Battelle manages ORNL for the DOE’s Office of Science, the largest single supporter of basic physical sciences research in the United States. RidgeAlloy was developed as part of the Office’s efforts to advance lightweight materials for transportation and energy systems.

Also read: The World of Aluminium Extrusions – Industry Forecast to 2032

Responses