Fiat Chrysler Automobiles, lightweight OEM parts supplier Nemak and Tennessee's Oak Ridge National Laboratory have collaborated to develop a new aluminium alloy for use in turbocharged engines, which is expected to offer better fuel economy.

The aluminium-copper-manganese-zirconium alloy (ACMZ) was developed in just under four years by the laboratory. ACMZ is affordable, lightweight and capable of withstanding temperatures 100 degrees Celsius higher (300 degrees Celsius or 572 F) than commercially available automotive cast alloys. The alloy is highly suitable for the next generation of more fuel-efficient internal combustion engines. Many aluminium heads today are made from 319 or 356 Aluminium, which cannot withstand temperature above 200 degrees Celsius (392 F).

The new alloy that FCA intends to use can withstand temperature because the silicon found in some aluminium alloys are replaced with copper; a rare combination for the automotive industry due to its tendency to crack after casting.

"When we focused on copper, other people in the industry almost laughed us off, saying we'd never be able to cast that," stated Gregg Black, senior manager of advanced powertrain engineering at FCA, in a company blog post. "We knew there was competition, including other teams working at Oak Ridge National Labs, but we outperformed everyone on this."

ORNL volunteered its Titan supercomputer to develop simulations for metal cooling, and later narrow down recipes for the new alloy to seven options. A team of materials, metallurgical and computational scientists led by ORNL’s Amit Shyam worked together on the development plan with help from industry partners FCA US and Nemak USA.

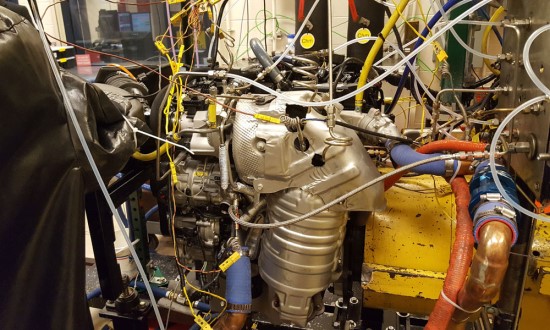

FCA and Nemak took the new alloy made by ORNL and tested more than 100 cylinder heads with structures identical to those of current FCA offerings. The 16HT/ACMZ alloys may allow engineers to streamline cylinder head designs for more complete combustion. The 16HT/ACMZ aluminium heads are projected to cost just 7% more than 319/356 aluminium heads. Its production does not require new manufacturing techniques other than the extra steps in the post-casting heat treatment.

Testing continues now with FCA and Nemak to evaluate the alloy’s performance and durability in engine applications and internal evaluations of ACMZ will continue throughout 2018. FCA will need a few years to roll off the production line for 16HT/ACMZ-headed engine.

Responses