In advanced fields like aerospace and space exploration, materials must combine low weight, high functionality, and resilience to extreme temperature fluctuations. Shape-memory alloys are promising candidates, offering impressive strength, toughness, and the ability to recover from deformation due to their superelastic properties.

Image Source: Nature / Research Paper

However, achieving low mass and reliable performance at cryogenic temperatures remains challenging. A team of researchers, namely Yuxin Song, Shunsuke Sato, Sheng Xu and Inho Lee, have developed a newly developed shape-memory alloy specifically engineered to meet these demanding requirements.

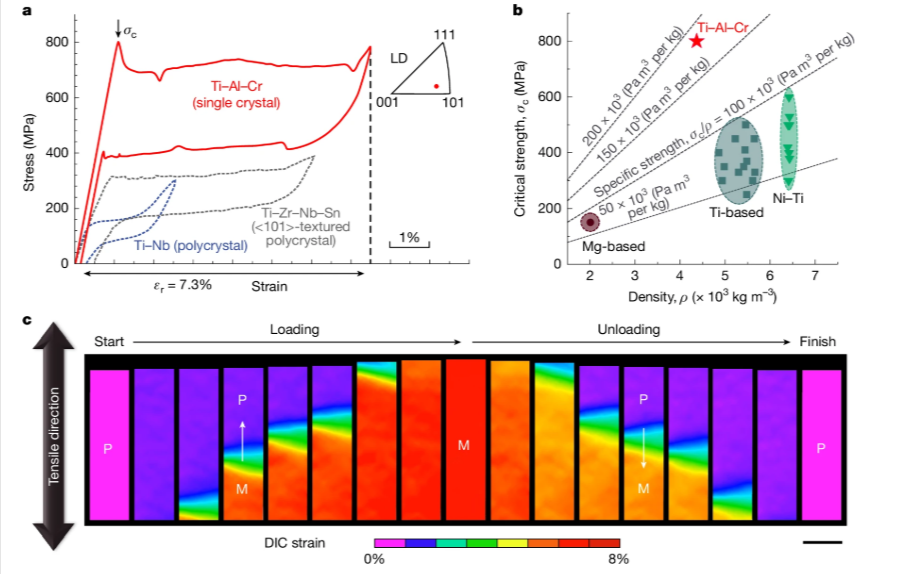

Composed of aluminium and titanium with a chemical composition of Ti₇₅.₂₅Al₂₀Cr₄.₇₅, this alloy features a low density of 4.36 × 10³ kg/m³ and a high specific strength of 185 × 10³ Pa·m³/kg at room temperature. It also exhibits outstanding superelasticity. This property results from a reversible stress-induced phase transformation between an ordered body-centred cubic parent phase and an ordered orthorhombic martensite phase, enabling a recoverable strain greater than 7 per cent.

This remarkable functionality remains stable across a wide temperature range from deep cryogenic levels at 4.2 K to above room temperature thanks to the unconventional temperature dependence of the transformation stresses. Notably, below a specific threshold during cooling, the critical stress required for phase transformation decreases as the temperature drops. This inverse relationship is attributed to temperature-sensitive anomalous lattice instability in the parent phase.

Also Read: NALCO’s INR 30,000C smelter expansion plan is on track, defies delay report

With its unique mechanical response and thermal adaptability, this alloy shows strong potential for high-performance applications in extreme environments such as deep space missions and systems involving liquefied gases and everyday technologies where flexible strain accommodation is essential.

The newly developed alloy, composed of Ti–20Al–4.75Cr in atomic per cent and referred to as Ti–Al–Cr, exhibits exceptional properties that set it apart among Ti-based shape-memory alloys. One of its key features is its strong tendency for abnormal grain growth, enabling the formation of large single crystals spanning several centimetres, which is ideal for mechanical testing.

The newly developed Ti–Al–Cr shape-memory alloy, part of the broader family of lightweight, strong, biocompatible, and corrosion-resistant titanium alloys, shows great promise across a wide range of applications thanks to its exceptional superelasticity over a broad temperature range. This characteristic is particularly valuable for interplanetary missions, such as NASA’s Artemis I, where materials must endure extreme environments while maintaining mechanical functionality. Narrower operational temperature windows limit existing solutions like Ni-Ti superelastic tyres designed for Moon and Mars exploration.

Responses