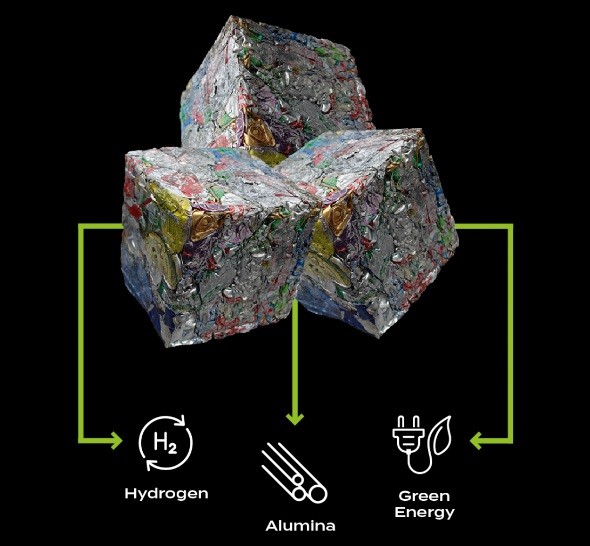

The U.S. government has proposed a $7 billion (for starters) investment for a much-needed advancement in clean hydrogen generation, which can be made possible with GH Power's groundbreaking technology that uses recycled aluminium and water to produce pure hydrogen. The hydrogen generated by the modular version of GH Power's 2MW reactor is pure and clean. It has zero emissions, zero carbon, and zero waste, even though it is made from just two inputs (recycled aluminium and water).

GH Power, known for building and operating energy reactors that deliver green base-load power, has created a one-of-a-kind renewable energy technology that uses exothermic processes to generate three highly desired green outputs: hydrogen, green alumina (aluminium oxide) and exothermic heat, thereby slaying three birds with one high-tech stone. Over the last seven years, GH Power has been developing a novel kind of reaction for hydrogen generation, and it is currently preparing to turn on the first commercial reactor of its sort in Hamilton, Ontario, Canada.

{alcircleadd}

This award-winning technology is the product of seven years of meticulous study by world-class scientists and engineers, directed by GH Power CEO Dave White, a power-generating industry veteran. The GH Power team has almost a century of combined power production expertise in designing, constructing, and operating power plants, refineries, and other energy infrastructure.

The commissioning of this nuclear reactor occurs at a pivotal point in the global energy transition. According to the Hydrogen Council, hydrogen will account for 18 per cent of all energy provided to end users by 2050, reducing 6 gigatonnes of carbon emissions yearly and generating an estimated $2.5 trillion in annual sales (not to mention creating 30 million employments worldwide).

The reactor at GH Power is self-sustaining, zero-emission, and a net energy generator for consumption. It is completely clean and modular, which means it can be installed on-site to power North America's businesses with clean energy for the first time while remaining cost-competitive with traditional fossil fuels. It also generates green hydrogen, exothermic heat, and valuable green alumina, which is utilised in various commercial applications ranging from lithium-ion batteries and LED lighting to semiconductor fabrication.

GH Power intends to build a facility to generate 11,700 tonnes of green hydrogen per year to power a 30 MW combined cycle plant with a net output of 27 MW. For the time being, the Department of Energy estimates that the cost of manufacturing hydrogen from renewable energy is about $5 per kilogram, around three times the cost of producing hydrogen from natural gas. The Department of Energy aims to reduce clean hydrogen production costs by 80 per cent to $1 per kilogramme within a decade.

According to the company's estimations, GH Power's reactor is already 60 per cent cheaper than electrolysis for hydrogen manufacturing and is a net energy provider to the grid. Its green alumina co-product production costs are more than 85 per cent lower than the most frequently used alumina manufacturing procedures, which depend on hydrochloric acid leaching and hydrolysis. This might be a game changer in the crucial sector's decarbonisation.

GH Power and its engineering team concluded Phase 1 testing of its 2MW reactor near Hamilton, Ontario, on June 30th, and Phase 2 testing started on June 30th. The next phase is to transition into commercial operations and 24-hour continuous operations. Revenue generation is expected to commence in the fourth quarter, to eventually scale up from two 2MW reactors to a 27MW Net Output power solution.

Responses