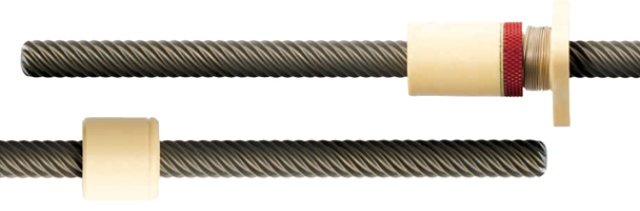

Igus, a worldwide manufacturer and distributor of plastic, has combined its tribologically optimised lead screw nuts with hard anodised aluminium lead screw.

Igus now offers lead screw units with aluminium lead screws which are three times lighter than stainless steel lead screws. The combination of efficient dryspin thread and hard anodised aluminium convinces by its more than 60% low weight and can be operated without lubrication and maintenance. The lead screw have special asymmetrical lead screw geometry, which in continuous operation offers up to five times longer service life than conventional solutions. With lead screw diameters from six to 20 millimetres, quiet operation and low vibration is possible even in confined spaces.

The lead screw have special asymmetrical lead screw geometry, which in continuous operation offers up to five times longer service life than conventional solutions. With lead screw diameters from six to 20 millimetres, quiet operation and low vibration is possible even in confined spaces.

Stefan Niermann, head of drylin linear and drive technology at Igus said, “Aluminium is not only very light and corrosion-free, but also achieves an extremely high wear resistance and low friction coefficients due to the hard anodising.”

{googleAdsense}

He further stated, “In conjunction with the geometry and optimised lead angles, the efficiency of the lead screw can be increased further and the required drive power can be reduced.”

However, the dryspin lead screw made of aluminium is suitable for a variety of applications for example, in aerospace, medical or food processing technology as well as reliable and cost effective solution for printers, filling plants or laboratory equipment. The user can select between right and left hand threads, between lead screw nuts with or without flange and additional options such as the anti-backlash feature.

Responses