您想继续阅读英文文章还

是切换到中文?

是切换到中文?

THINK ALUMINIUM THINK AL CIRCLE

While aluminium is being valued for its top-notch recyclability and strength, prolonged exposure to heat causes conventional aluminium alloys to lose strength, limiting their use in engines, turbines, and aerospace systems. However, this long-standing limitation is addressed by a research team of Nagoya University in Japan, who have developed a new family of aluminium alloys.

The new version of aluminium retains strength even under extreme heat. Simultaneously, it remains highly recyclable and suitable for metal 3D printing. Designed specifically to address the aerospace and automotive uses in mind, the new family of aluminium is a bold step towards expanding aluminium’s role in high-temperature applications.

Explore- Most accurate data to drive business decisions with 50+ reports across the value chain

Turning weakness into a strength

The research team took an unconventional take in designing this alloy by using iron as a key element in the new alloy. Though iron is usually avoided in aluminium alloy due to its tendency to cause brittleness and corrosion, the team led by Prof. Naoki Takata focused on controlling the behaviour of iron in aluminium structure, rather than excluding it completely. A careful combination of iron with selected elements facilitates solidification and overcoming its typical drawbacks.

Read More: Aluminium scrap resists declines and supports costs, with ADC12 prices continuing to hover at highs

Rewriting aluminium’s internal structure with 3D printing

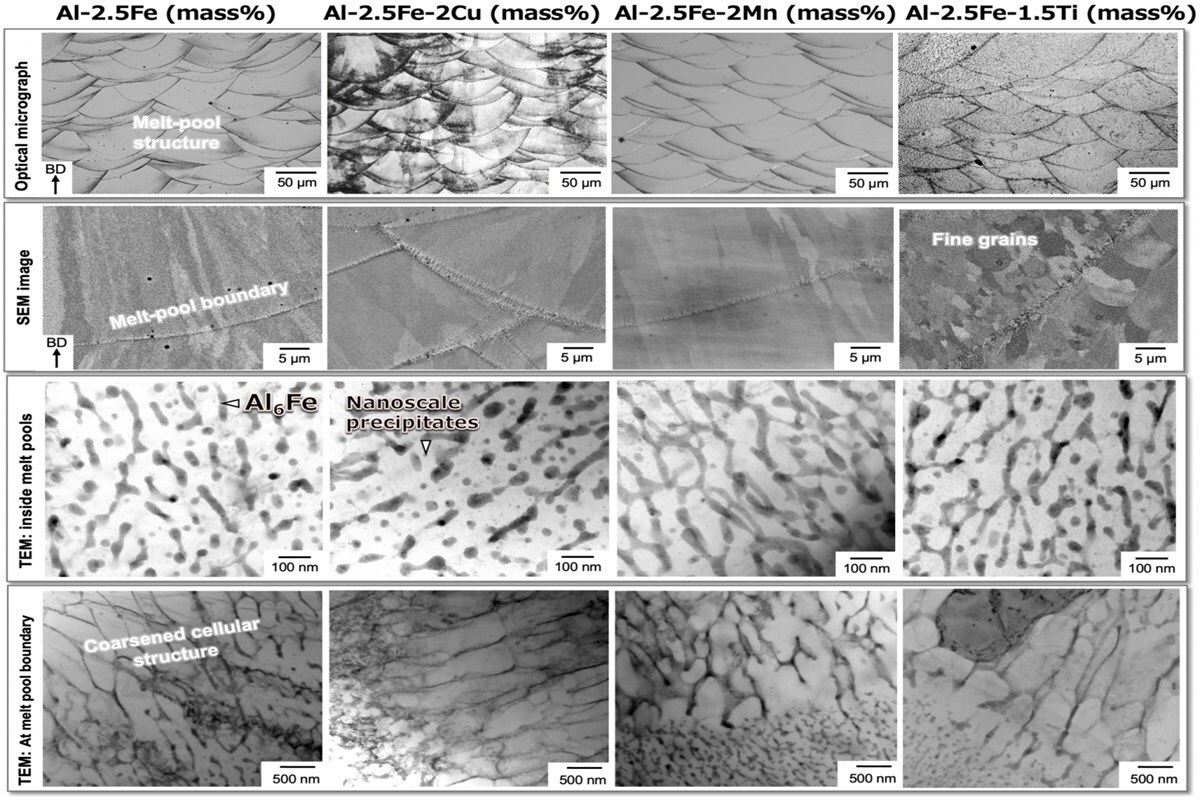

The breakthrough fundamentals are based on laser powder bed fusion, which is a 3D printing process where metal melts and solidifies within seconds, creating rapid cooling that shapes the alloy’s structure from the core. This technology locks iron and other elements into metastable forms, which is otherwise not achieved through conventional manufacturing techniques. Leveraging a systematic design approach, the research team identified elements which reinforce the aluminium matrix and form protective micro and nano-scale structures, improving strength and heat-resistance without affecting printability.

Al-Fe-Mn-Ti: a standout alloy composition

Among the newly developed alloys, the formulation of Al-Fe-Mn-Ti proved particularly successful. Composed of iron, aluminium, manganese, and titanium, Al-Fe-Mn-Ti comes with the rare balance of properties, which helps in retaining its strength in temperature conditions as high as 300°C while being flexible at room temperature.

In terms of performance, this one surpassed other aluminium alloys produced through 3D printing and showed fewer issues than conventional high-strength alloys during fabrication. While the latter is subject to cracking or warping when processed under laser power bed fusion.

Aluminium’s feasibility in the automotive and aerospace Industries

In the high-temperature automotive components, the new alloy could easily replace heavier metals. Thus, improving field efficiency and lowering emissions. In aerospace, they may enable lighter engine parts, such as turbines and compressor rotors, without sacrificing performance. Precisely, the research offers a blueprint for designing metals, specifically for additive manufacturing, potentially accelerating material development across industries.

Wider shift in aluminium additive manufacturing

Nagoya University’s research is a part of the global effort to enhance aluminium’s performance in additive manufacturing. Lately, there’s an increasing focus in the research labs in overcoming the material limitations that have so far put a restriction in aluminium’s use in demanding environments.

In September, the US Department of Energy’s Oak Ridge National Laboratory tested a new aluminium alloy known as DuAlumin-3D for high-temperature automotive applications. The tests showed that the alloy performed better than some conventional aluminium materials during laser powder bed fusion, where cracking is a common problem. Simultaneously, it can perfectly retain its thermal properties better than the established alloys, supporting its key role in the lightweight vehicle design and optimum fuel efficiency.

Elsewhere, Aluminium Materials Technologies worked with the University of Birmingham to examine the metallurgy of another 3D-printed aluminium alloy, A20X. Their research covered both laser powder bed fusion and direct energy deposition techniques, examining how composition, heat treatment, and processing parameters influence performance.

A20X is known for its isotropic properties and a high-strength aluminium-copper alloy, which remains consistent in various environments. This is widely being used in aerospace and motorsport applications, and the collaboration aimed to better understand how additive manufacturing could further enhance its capabilities.

Recent developments reveal a decisive shift towards designing aluminium alloys for additive manufacturing rather than simply adapting existing materials. The research at Nagoya University made it clear that the metals once considered unsuitable for crafting aluminium alloys can ideally perform better if paired with the right processing methods. As demands grow for lighter, stronger and heat-resistant materials, such innovative discoveries could reshape aluminium’s role in future engineering.

Must read: Key industry individuals share their thoughts on the trending topics

Responses