Aluminium dross, a byproduct of the aluminium smelting process and an unavowed mixture of metallic aluminium, aluminium-oxide and oxides of numerous alloying elements, have been finding its way to landfills for years. It is only recently that the aluminium industry came to realize its significance as a secondary source of the metal. Industry estimates suggest that an increase of 10 tonnes of aluminium dross recovery can augment production of the metal by about 3.2 tonnes. And that is not all! Aluminium dross recycling has immense environmental benefits and the processed dross can be used to produce a number of other commercially valuable products too.

Aluminium dross recycling addresses sustainability concerns of the industry

Today, rising pollution, too much of energy loss and natural resource waste have raised a red flag that no industry can afford to overlook. The stakes are way too high and ignoring the effects can cost the industry its very existence. Aluminium industry started considering aluminium dross recycling primarily keeping these sustainability issues in mind- the key objectives being:

Secondly, aluminium dross if left untreated interferes into the natural microbial activity in the waste and ignite or pyrolysize surrounding solid waste materials. Chemical reactions involving aluminium can also release large amount of highly toxic and/or flammable gases which can aggravate pollution manifold.

This is exactly why the 10,000 tonnes of partially-treated dross from Tiwai aluminium smelter by in the former Mataura paper mill is adding to the concerns of people residing in the Southland region of New Zealand. The aluminium dross that are left at the paper mill by the processor is now being viewed as a liability no entity is ready to buy.

New Zealand First MP Mark Patterson said recently, "There's a lot of everyone wanting someone else to take responsibility, and that's clearly not good enough for the people of Mataura who are sitting on a toxic dump right by their river, so we have to sort this out."

However, this is an unlikely fate the dross is reduced to. Studies show that aluminium dross can be used to develop many value-added products.

Commercial applications of aluminium dross:

Improved economics to drive global aluminium dross recycling trend

Aluminium dross processing and dross recycling technologies have undergone significant advancement in the last few years. An increase in 10 tonnes of dross recovery has augmented aluminium production by about 3.2 tonnes.

As per latest data, aluminium dross generated across the world reached an estimated 3 million tonnes in 2017. Asia pacific region accounted for 56% of the total dross generation followed by Europe, North America and Middle East & Africa.

Aluminium Dross Recycling has just picked up. Given the increasing relevance of sustainable aluminium industry development, the trend will flourish in the years to come.

To gain more insight into the trend, Buy AlCircle sector focus report Aluminium Dross Processing: A Global Review.

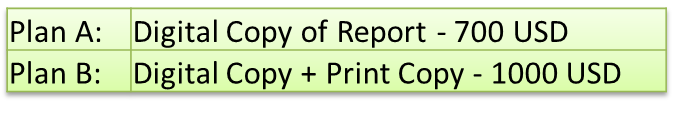

It is available in both digital and print formats. The pricing details are as follows:

For corporate package and other query write to booking@alcircle.com.

Responses