Hycast, a technology company committed to delivering sustainable and safe casthouse solutions. We claim and endeavour to be the best at what we do. Our technology enables the production of aluminium products of superior quality through fully automated casting lines for Billet and Slab, including our unique drain-free melt treatment units. For our customers, this means a safe casthouse, sustainable solutions, increased value creation and competitive market advantages.

Now, we are proud to present Hycast Insight, which will revolutionise the way operators monitor the product during a cast.

The in-house developed camera solution located underneath the casting table will patrol back and forth between the rows of billets, removing the need for operators to manually check the cast on the Casthouse floor.

So why invest in Hycast Insight? You can remove the operators from the molten metal area, which is a huge safety improvement in the Casthouse. In addition, you will have:

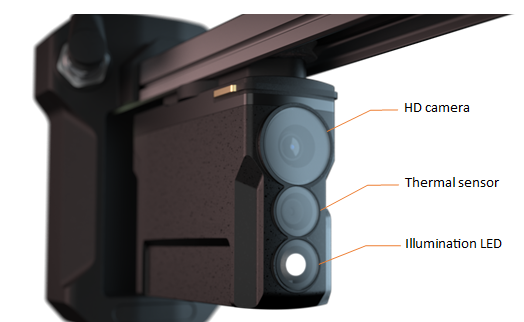

Figure 1: Robot front

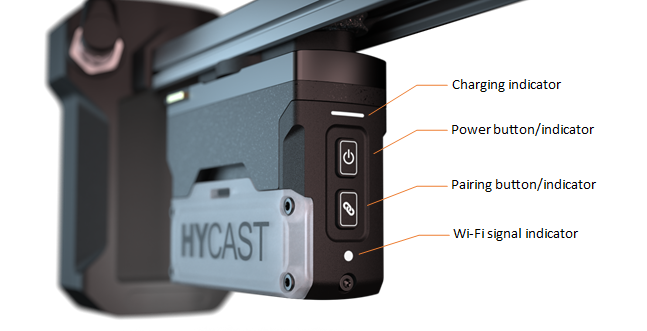

Figure 2: Robot back

The main system consists of a compact-size camera robot with Wi-Fi communication, an HD camera, a thermal sensor, a light source, auto-scan mode, and manual control. A docking station protects the robot during start-up, end of cast and between casts and provides power to charge the robot. The HMI system provides an overview of all cameras, the positions of the robots, control for auto-mode and controls for light and manual control. The system can also be integrated into the Casting Control system, and data can be recorded for historical trending if necessary.

Responses