Honeywell Aerospace a Phoenix-based manufacturer of aerospace parts has commissioned a new aluminium 3D printer laboratory. This is an expansion of their existing Phoenix Additive Manufacturing Center near Phoenix Sky Harbor International Airport.

Aluminium is a preferred metal for manufacturing aerospace parts because of its lightweight and anticorrosive qualities. Donald Godfrey, an engineer in charge of Phoenix lab believes that having an in-house facility to work with the metal will cut costs to the company.

{alcircleadd}“This is the first aluminium lab in North America. Aerospace applications prefer aluminium and space is a huge part of our business. Doing this in-house is cheaper and faster. We’re paying for the machines just in our savings,” he said.

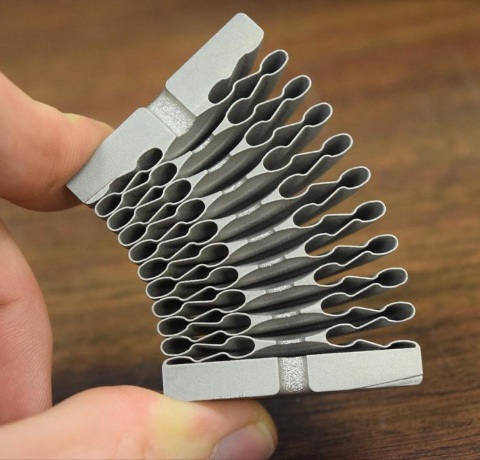

The aluminium 3D printing lab is equipped with seven 3D printer machines and will soon start manufacturing aluminium equipment and parts for Honeywell. The company has been using 3D printing technology for eight years with a variety of printers. The facility uses lasers, electron beams and sand to print a variety of parts in nickel and now they will be using the technology to make aluminium aerospace parts.

“We can print tools faster and cheaper without the need for mass manufacturing,” Godfrey said. “This is the future of manufacturing for America.”

He gave a real time example to show the effectiveness of the technology. Compared to a supplier who needed $400,000 and 10 months to manufacture a gear box, Honeywell employees could print the part in four days for $40,000 in the manufacturing lab.

The company spent $5 million to build the nickel 3D printer lab, and in just six months has brought in $22 million for government-funded research.

“We’ve paid for this lab in scheduled savings and tooling,” he said. “It’s how you reduce costs of manufacturing. All technology will be pushed in supply chain,” he added.

The lab used special grounded floor coating, anti-static mats and other lab specialties for safety as aluminium in a powdered form tends to be explosive.

Godfrey is also building a 30,000-square-foot lab for more 3D printing capacity in the campus near Phoenix Sky Harbor International Airport. The new lab will have another 10 to 16 3D printers for manufacturing faster, cost effective and quality parts for aerospace.

Responses