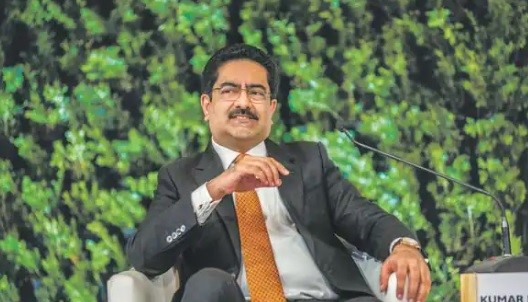

Hindalco Industries Limited plans to invest around INR 2,000 crore to bring new extrusion and fabrication technologies to India, critical to the country's construction of Vande Bharat trains with aluminium bodies. The announcement was made by Kumar Mangalam Birla, chairman of Hindalco Industries Limited, at the company's 64th annual general meeting (AGM).

"We are excited to partner the Indian Railways and the passenger coach manufacturing ecosystem for the ambitious high-speed Vande Bharat trains. An investment of ₹2,000 crore is planned for the project and technology tie-ups are in place to bring new extrusion and fabrication technologies to India," said Kumar Mangalam Birla, chairman of Hindalco.

The company also announced another investment of INR 2,000 crore to build India's first copper and e-waste recycling plant. It will collaborate with EV OEMs to co-develop components like battery enclosures, motor housings, busbars, and more. The announcement for the construction of the aluminium bodied Vande Bharat trains was made in 2022.

Hindalco, India's largest metals company, has been involved in the railway industry, having previously commercialised the country's first all-aluminium low-weight rake. The Indian aluminium major, Hindalco Industries, hopes to assist Indian Railways in its carbon-reduction efforts. Its lightweight aluminium rake allows for faster speeds and heavier freight every trip, saving nearly 14,500 tonnes of CO2 during its lifespan.

The aluminium and copper manufacturer is expanding into the 'green' EV market with India's first copper and e-waste recycling facility. E-waste is often regarded as the most hazardous waste stream worldwide, and its hazardous character is exacerbated by inappropriate processing, resulting in considerable material loss. Due to a lack of modern metal extraction and refining technology in the United States, a significant amount of e-waste is being shipped to foreign countries.

Responses