Henan Yirui New Material Technology is a wholly owned subsidiary of Henan Mingtai AL. Industrial started the production of the new aluminium hot rolling mill supplied by the SMS group. The first coil was successfully rolled on November 22, 2023. However, two months before the contractually agreed date, the inaugural aluminium coil was successfully rolled on the recently commissioned hot mill at Henan Yirui New Material Technology Co., Ltd.

This hot mill represents a pivotal component of Henan Yirui's strategic expansion project, a Henan Mingtai group subsidiary in Gongyi, Henan Province, China. The early success underscores Henan Yirui's confidence in the competence and experience of SMS group, given its track record of achievements in the aluminium industry.

"A particular challenge was the seamless integration of second-hand equipment into a most modern four-stand tandem mill. We at Henan Yirui were convinced by SMS' solution and ultimately impressed by its smooth implementation. The new SMS X-Pact® Level 2 process model controls the re-used roughing mill and the new finishing mill, thereby creating a fully integrated 1+4 aluminium hot strip mill," said Liu Jie, General Manager of Henan Mingtai Aluminium.

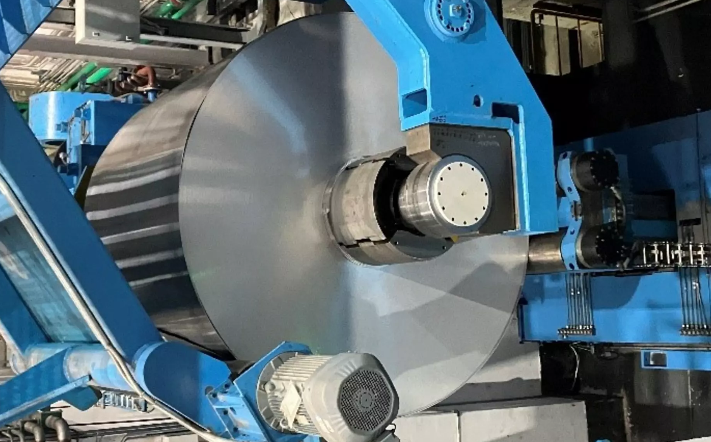

SMS group devised an innovative solution by refurbishing and integrating components from a second-hand 1+1 hot rolling mill, including a roughing mill and a single-stand finishing mill, into the 1+4 hot strip mill at the Gongyi facility. SMS supplied the mechanical equipment and provided fluid systems, X-Pact® electrical equipment, and process automation.

The new setup incorporates three state-of-the-art finishing mill stands featuring cutting-edge CVC® technology, ensuring superior strip quality. The mill exit area is equipped with a side-trimming shear of novel design, a down coiler unit, and an offline strip surface inspection station. The new hot strip mill can produce trimmed strips up to 2,150 millimetres wide.

The initial plan had slated the rolling of the first coil for the first quarter of 2024. Nonetheless, the installation and commissioning times were substantially reduced due to the exceptional technology and the remarkable efforts, dedication, and commitment exhibited by Henan Yirui and the SMS group. The Chinese aluminium manufacturer is extending its prosperous partnership with SMS group, which was initiated by acquiring a six-high cold rolling mill and an AMOVA high-bay coil storage system.

Responses