Austria-based high-quality aluminium products supplier Hammerer Aluminium Industries (HAI) celebrated the inauguration of its new P61 extrusion press line and logistics centre at its headquarters in Ranshofen, Austria. The event, which drew guests from local government and business sectors, marked not only the unveiling of the state-of-the-art press line but also the successful conclusion of a €125 million investment initiative that the HAI Group embarked on in 2022.

Image Source: Light Metal Age

According to Light Metal Age, the new press line expands capacity and enables the production of highly complex aluminium profiles for the automotive sector. The recently completed €125 million investment package encompassed a diverse range of projects.

About the new P61 press line

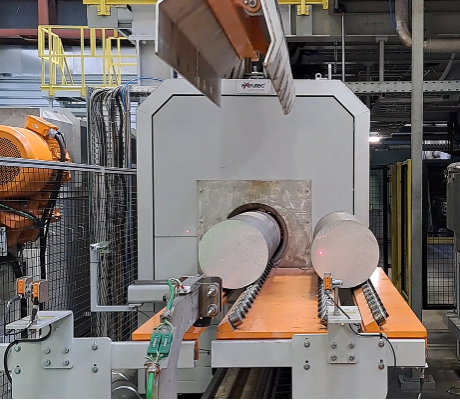

The P61 line includes a 60 MN, 12-inch front-loading press from Presezzi Extrusion, designed to handle billets from 600 mm to 1,750 mm in length. Crafted entirely in Italy, this new press delivers high extrusion speeds and operational flexibility while achieving exceptional energy savings and reducing maintenance needs. Its Energy Saving System (PE.E.S.S.) enhances efficiency by activating the hydraulic pumps only when necessary during extrusion.

Equipped with a modern automation system, advanced technological packages, and sophisticated sensors, the press supports proactive management by operators and maintenance personnel. The integrated PE software package provides a web-based telemetry system that collects data to enhance production and maintenance. This system can automatically gather samples at a rate of up to 20 microseconds, enabling detailed analysis and optimisation of performance.

The log handling and press feed systems for the P61 press were provided by Extrutec. The vertical log storage unit features 28 slots, each accommodating 12 logs (12 inches in diameter), allowing for a total capacity of 336 logs. It is equipped with a 2-axis crane for moving logs to the preparation area. Logs are pre-heated using the Eco Shower Unit (ESU), a patented hot-water system that boosts throughput and reduces energy consumption by up to 17 per cent.

As per Light Metal Age, the new press line enables the extrusion of approximately 15,000 tonnes of advanced automotive profiles per year, depending on the product mix. This increases the total extruded product capacity at the Ranshofen plant to around 50,000 tonnes and the overall capacity for the HAI Group to approximately 125,000 tonnes.

Image Source: Light Metal Age

About ESU

The ESU is integrated with a high-pressure log washer (3,000 PSI) to effectively remove surface contaminants. Heating of the logs is accomplished using two furnaces: a log furnace and a standalone induction furnace. The log furnace features a 15-foot high-velocity convection pre-heating section and a 30-foot gas-fired direct flame impingement section, achieving a throughput of 23,800 lbs/h. The induction furnace includes:

The log heating area features several components to support efficient billet preparation. This includes a billet taper quench, a hot saw equipped with a chip shredder and exhaust (5 mm kerf), and an overhead manipulator for transporting the billet through the preparation area to the press loader. Extrutec also provided an electric chest-style oven for pre-heating bolsters and an eight-chamber die oven with an automatic charging shuttle.

"The process for planning the line and selecting the equipment suppliers was actually very simple. We started operation of the P60 12 inch press about a year and a half ago and put a lot of energy into it to make it run perfectly. By ordering the same press we could reduce the startup time of P61 to only one month, with it running at the same productivity as P60," added John van den Nieuwelaar, technical managing director of extrusion at HAI Group.

Post extrusion process

Post-extrusion, the profiles are extracted from the press using a single puller and flying saw puller from Reisch Maschinenbau, who also supplied the lead-out and run-out tables. The profiles are then cooled using an α-flex soft-cooling quench from Extrutec. This quench features adjustable nozzle stocks (±30°) for targeted cooling, with parameters such as angle and pressure set via simulations based on the actual profile geometry.

SPS Technik also supplied automated stackers, cranes, floor conveyors, and packing systems, enabling fully automated basket handling and ageing without the need for manual labour or forklifts. The system features an advanced labelling system that marks aluminium profiles immediately after quenching, ensuring complete traceability and quality assurance. It includes scrap markings and sample identifications to assist HAI in meeting industry standards.

"The main feature of the P61 press line is its ability to produce complex automotive shapes with a high level of automation and process control," noted van den Nieuwelaar. "This starts with the line's advanced billet heating system and a best-in-class press and a runout with advanced cooling, stretching, and stacking."

Ranshofen facility since1950s

Although HAI was established in 2007, the Ranshofen facility has been operating as an extrusion plant since the 1950s. With the introduction of its latest P61 extrusion line, the site now boasts three modern 12-inch presses and one 10-inch press, primarily processing billets from the company's SustainAl line of low-carbon alloys.

Before installing the P61 extrusion line, HAI undertook a realignment of the Ranshofen facility, which included relocating a 25 MN extrusion line to the Chisineu-Cris facility in Romania and moving the previous logistics area to the newly constructed logistics centre. This reorganisation created the necessary space for the new extrusion line's construction and installation.

To expedite the setup of the new P61 press line, HAI decided to replicate the design of the P60 line installed in 2022. Consequently, the new line utilises equipment from the same suppliers, including Presezzi Extrusion Group, extrutec GmbH, SPS Technik GmbH, and Reisch Maschinenbau GmbH.

Updated logistics centre

HAI has enhanced its Ranshofen site by addressing the previously overcrowded logistics area. The company has built a new 14,000-square-meter logistics centre featuring a modern warehouse and loading area that accommodates multiple lorries simultaneously for efficient loading and unloading. The cutting-edge facility includes an advanced high-bay racking system from SIBA System Integration GmbH, which offers 2,220 storage locations for customer load carriers. This system automates the storage and retrieval of customer pallets, streamlining operations and improving efficiency.

Different projects included

In Romania, HAI commissioned a new Hertwich multi-chamber melting furnace at its Santana plant in early 2022, followed by the installation of a 40 MN extrusion press line at its Chisineu-Cris facility in 2024. At its Soest site in Germany, the company expanded its operations with a 2,600 sq m production hall in 2024, adding modern CNC and assembly systems to enhance fabrication capacity for ready-to-install components. In Ranshofen, Austria, HAI installed two 60 MN extrusion press lines—the first in 2022 and the second in June 2024—along with significant upgrades to the logistics area.

"We have become the technology leader in lightweight aluminium components for the transport sector at the Ranshofen site. With the new P61 and the entire upstream and downstream processes, we can produce highly complex aluminium profiles with excellent crash properties for Europe's renowned OEMs. This step was strategically important and today's inauguration fills us with pride," said Rob van Gils, CEO of HAI.

With the completion of this investment plan, HAI now operates 13 extrusion lines across its European facilities, increasing its total production capacity to 125,000 tonnes per year. This is complemented by the company's annual recycling and casting capacity of 250,000 tonnes, which helps ensure a steady supply for its extrusion operations. Together, these capabilities solidify HAI's position as a European aluminium extrusion industry leader.

Future growth

With the completion of HAI's European investment plan, the company is well-positioned to meet the growing demand for low-carbon, high-quality extruded aluminium products across the automotive and other industries. Building on this success, HAI is now turning its attention to its first venture outside Europe.

The company has entered into a joint venture agreement with LS Cable & System to establish a new facility in South Korea aimed at producing complex extruded aluminium components for the local electric vehicle market. In April 2024, the two companies broke ground on a €46 million project in Gumi. The 13,800 sq m production hall will feature a 60 MN extrusion line, identical to the recently completed P60 and P61 lines in Ranshofen, including the same equipment suppliers. The new facility is expected to commence operations in 2025.

Responses