South32 Limited, a mining and metals company headquartered in Perth, Western Australia, has secured $4.4 million government funding to accelerate its carbon emission reduction efforts at Worsley Alumina Refinery, which will eventually bring the company close to its net-zero carbon emission goals by 2050.

Image source: ARENA

{alcircleadd}

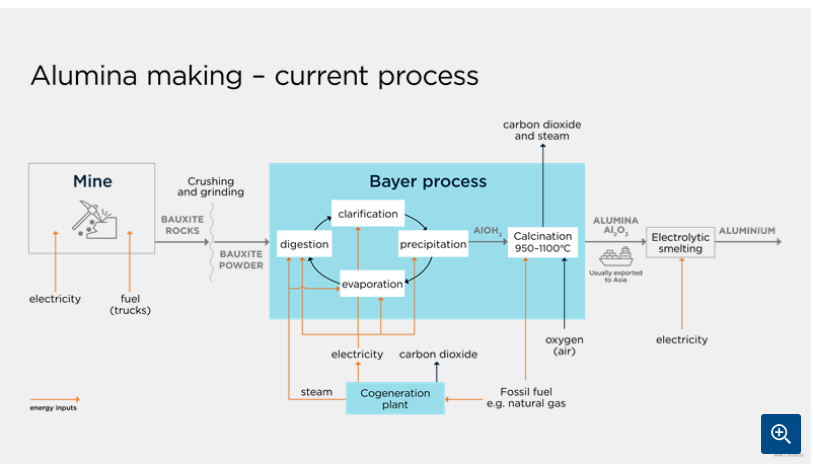

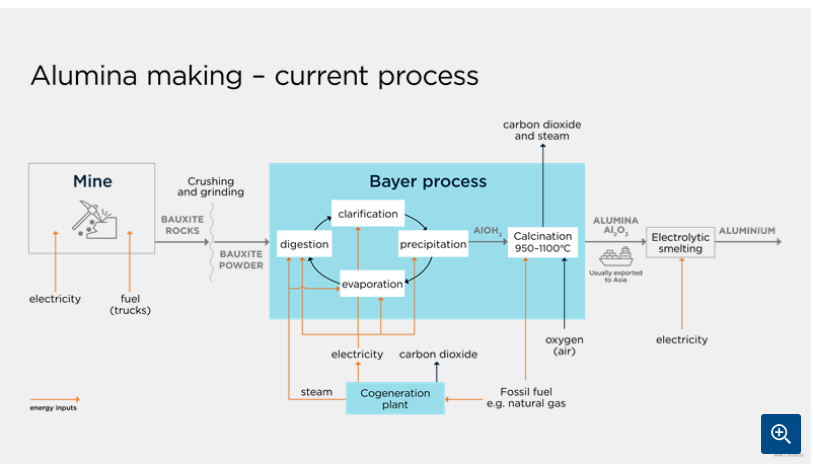

The Australian Renewable Energy Agency (ARENA) said the funding would support South32 in conducting a pre-feasibility study to examine four investment options for partially replacing fossil fuel-based steam generation with renewable energy-powered systems at Worsley refinery. This shift will enable the company reduce direct carbon emissions from burning fossil fuels, leading to a more sustainable future.

This funding is part of ARENA’s $400 million Industrial Transformation Stream programme, which aims to reduce carbon emissions from some of the most energy-intensive industries, such as alumina refining.

ARENA CEO Darren Miller said: “Meeting Australia’s emissions reduction targets will require businesses in the most energy intensive industries to incorporate renewables in their operations. Funding from ARENA will help South32 investigate innovative electrification options for steam generation that enable the use of renewable energy.”

Four keys to drive decarbonisation in alumina refining

- Mechanical vapour recompression - MVR replaces traditional natural gas boilers by using renewable electricity to produce steam. This technology alone could cut emissions from alumina refining by up to 70 per cent. By capturing and reusing process steam, MVR significantly enhances energy efficiency.

- Electric boilers - Powered by renewable energy, electric boilers offer a low-emission alternative to coal or gas-fired systems for steam generation. As a mature technology, low-temperature electric boilers could be deployed at some refineries before 2030. However, their adoption is currently limited by higher operating costs compared to fossil fuel-based systems.

- Hydrogen calcination - Hydrogen calcination substitutes natural gas combustion in the calcination process with hydrogen. When combusted with oxygen, hydrogen produces a pure steam exhaust that can be captured and reused, especially when integrated with MVR. In 2021, with $580,000 funding from ARENA, Rio Tinto’s Yarwun refinery in Gladstone had launched a feasibility study to examine the possibility of constructing a hydrogen pilot plant and to assess hydrogen’s role in refinery operations.

- Electric calcination – This technology replaces fossil fuel-based calciners with electric systems powered by renewable energy. Although still at a relatively low level of technical maturity, this approach holds substantial promise. In April 2022, ARENA awarded $8.6 million in funding to support Alcoa’s demonstration of electric calcination technology at its Pinjarra alumina refinery.

Also read: https://www.alcircle.com/news/alcoa-to-install-steam-run-mvr-module-in-its-australian-alumina-refinery-saving-excess-energy-usage-89972

Green tech + renewables = 98% carbon emission reduction