Green Critical Minerals is drawing increasing attention from international customers and industry partners as it progresses its innovative VHD graphite technology toward commercial-scale production.

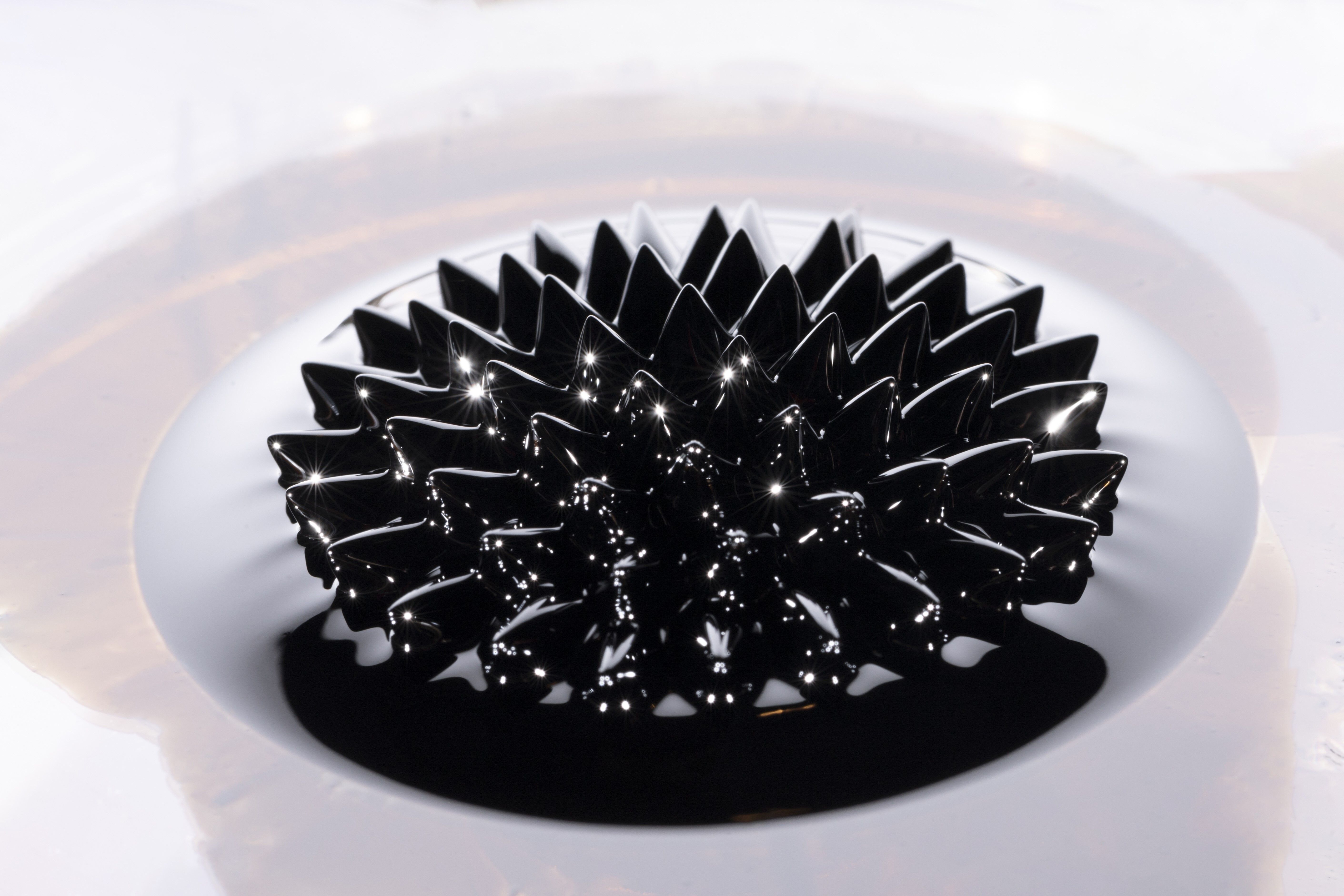

Image for representational purposes

The company recently announced significant results from finite element modelling commissioned to international specialist Professor Qing Li, focused on the thermal performance of the VHD graphite heat sink.

Graphite heat sink is closely related to aluminium because both materials serve vital roles in thermal management, especially for electronics and microchip cooling.

Aluminium has long been the industry standard due to its high thermal conductivity, lightweight nature, affordability, and ease of manufacturing. It efficiently absorbs and transfers heat from microchips, preventing overheating and ensuring stable device performance.

In recent tests comparing Green Critical Minerals’ VHD heat sink with conventional materials, the VHD technology demonstrated a significant ability to reduce the operating temperatures of high-performance microchips.

The VHD heat sinks managed power loads between 300 and 400 watts at temperatures ranging from 70 to 85 degrees Celsius, substantially outperforming the typical 200-250 watts capacity of traditional heat sink materials.

In aluminium production, heat sinks are primarily used to dissipate heat generated during smelting, casting, and extrusion processes, ensuring that equipment such as furnaces, molds, and power electronics maintain optimal temperatures for efficient operation.

Market potential and future outlook

Green Critical Minerals is also exploring applications of VHD technology beyond heat sinks, including cold plates used in liquid cooling systems.

Booth added, “We have a standout and in-demand product that is needed across several large and growing markets and look forward to executing on a busy work program […] and generating first revenue in the first half of 2026.”

The company emphasises that effective thermal management is essential for operational stability and cost efficiency in data centres and other high-demand environments.

Booth said, “Effective thermal management is critical for ensuring operational stability and performance continuity in such environments, in reducing data centre capital and operating costs and supporting sustainable data centre development.”

With positive test results, Green Critical plans to expand discussions with global thermal management providers and semiconductor manufacturers, expecting a steady stream of updates, including customer progress and initial sales agreements, through 2025.

Note: To feature your brand and share insights, contribute an article or interview in our forthcoming e-magazine "Sustainability & Recycling: Aluminium's Dual Commitment."

Responses