Graphene Manufacturing Group Ltd. has unveiled the update of its Graphene Aluminium-Ion (G+AI) battery technology, which has been developed in partnership with the University of Queensland under the supervision of a joint development agreement with the global mining giant Rio Tinto. Alongside this, the firm has secured the required support from the Battery Innovation Center in Indiana, USA.

With consideration to its current state in terms of development, GMG’s G+AI battery reflects some outstanding performance in comparison to high-end Lithium Titanate Oxide (LTO) batteries, which can cost as much as USD 1,500 per kWh. Development of the GMG’s G+AI battery can be efficiently done at much lower cost, giving a hard competition to LTO options. Tracing back to the start of 2025, the global sales of the LTO batteries, which are used in various applications, made around USD 5.6 billion.

Talking about the battery performance

The firm, with its latest battery, has announced that after the development phase is completed, it will be capable of meeting all the important and targeted specification requirements. This performance agility includes charging in less than six minutes, achieving an energy density of over 100 Wh/kg after an hour of charging. In addition to this, the battery will also provide a long cycle life of up to 10,000 cycles, which shall perform without the use of lithium. This technology is set to enhance safety by reducing the risk of thermal runaway, which could mean an eliminated need for a separate thermal management system.

Bob Galyen, the Non-Executive Director at GMG stated, "In my nearly five decades in the battery industry, I have rarely seen a technology with the disruptive potential of GMG's next-generation graphene aluminium-ion battery."

The battery, with the capability to charge from empty to full in under six minutes, is making a clear distinction for designers in electric vehicles, consumer electronics and stationary storage. This further eliminates the need to plan for long charge stops and bulky battery packs, enabling engineers to seamlessly create systems, which allows them a quick energy turnaround, higher power output and enhanced safety.

Also read: Enpack secures a 50 million m² aluminium composite foil deal

For the years to come, it is estimated that the lithium-ion batteries will still be a key player within the energy sector, but certain factors like fast charging, temperature tolerance and reliance on critical minerals are becoming pretty clear. With the inclusion of graphene and aluminium, the firm is trying to reduce the dependency on the traditional lithium-based systems, which aids in achieving significant charging time improvements, along with the power density.

As the firm moves from lab development to large-scale manufacturing, it is making sure to have enhanced reliability, safety and make it cost-effective at the industrial level. Partners like automotive, grid and specialty device are currently looking to develop collaboration for further exploring the pilot programs and enter the early-stage integrations. This shall place the firm at the forefront of the next wave of electrification powered by graphene aluminium-ion technology.

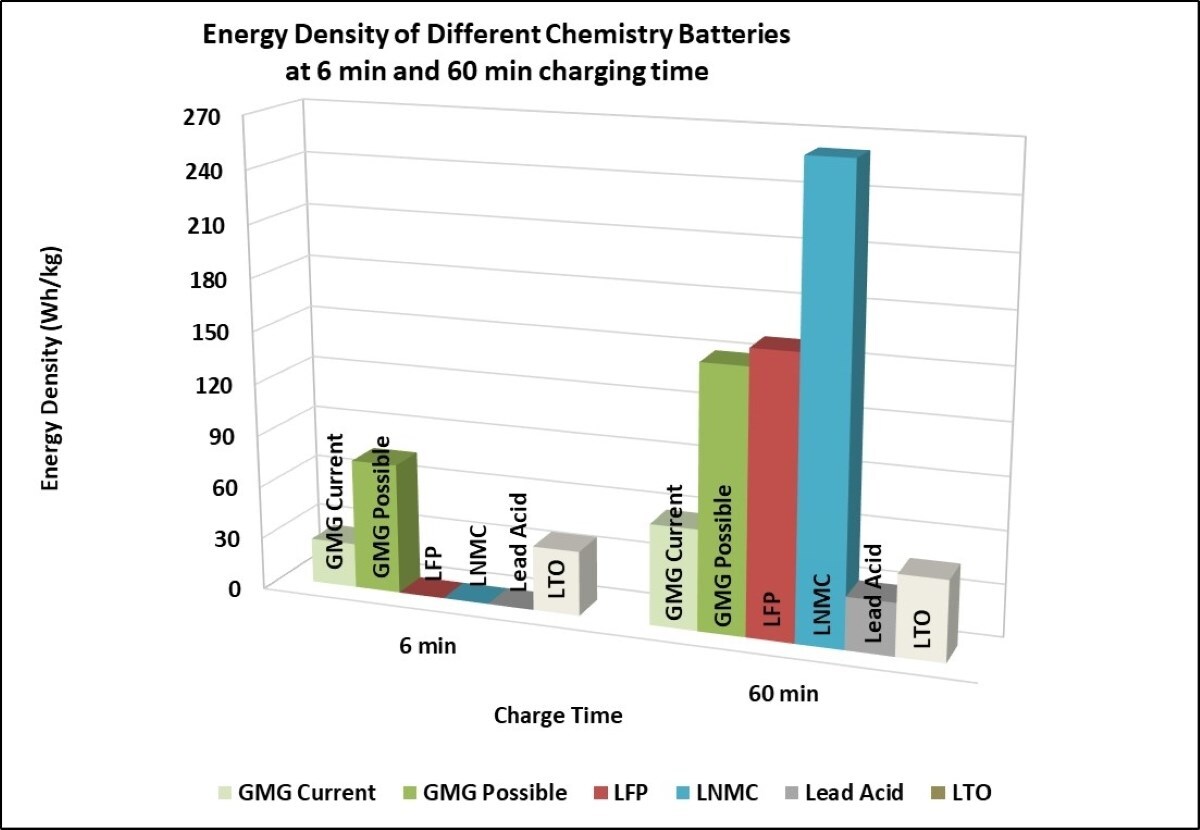

Energy density upon charging

After conducting the testing while still in the development phase, the firm's and BIC's batteries are deemed to reach the energy density of 58 Wh/kg after being charged for an hour and 26 Wh/kg when charged in just six minutes. Within 3.2 minutes, the batteries are able to get charged up to 62 per cent of their capacity. These batteries run at a nominal voltage of around 3.0 volts and have shown consistent performance over hundreds of cycles with that six-minute fast charging, without the major degradation, which is usually seen in lithium-ion and sodium-ion batteries under similar high-rate charging conditions.

Figure 1: Different Battery Chemistry Performance at 6 min and 60 min Charge

Standard commercial lithium nickel manganese cobalt (LNMC) and lithium iron phosphate (LFP) battery cells, which are commonly used in stationary storage and electric vehicles, do not provide the rapid six-minute charging at 10C. These types of battery cells are typically designed with charge rates that take around an hour or more (1C) or two hours (0.5C). However, these specialised high-power cell designs, like the LTO battery cells, are capable enough to provide such tolerable charge rates of 6 minutes (10C).

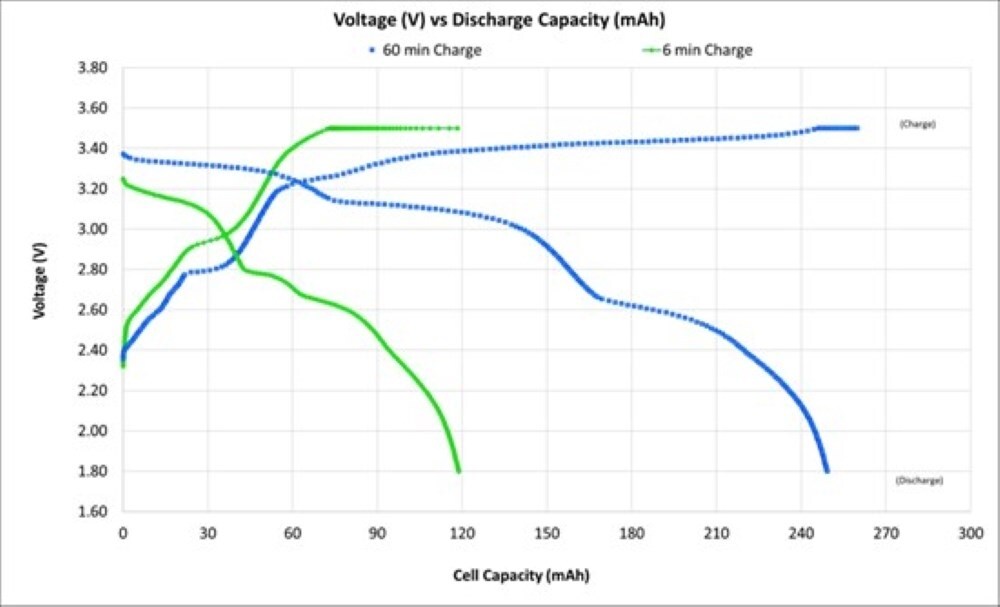

Figure 2: Battery performance curves of GMG's G+AI Battery at 60 min and 6min charge

Don’t miss out- Buyers are looking for your products on our B2B platform

A completely new hybrid electrolyte

At present, the firm has introduced a completely new hybrid electrolyte, which is deemed to be free from chloride and noncorrosive, which is common in aluminium battery electrolytes, besides the complex cathode and anode technology, which aids in stable charging for many cycles. Within the firm's latest battery innovation, the use of aluminium foil enables the base for both the cathode and anode. This offers a benefit in terms of cost and weight, which is compared with copper substrates, which are usually found in the lithium- and sodium-ion batteries. Currently, the firm has also submitted another patent application for safeguarding the advancement it has made so far.

Craig Nicol, the Managing Director and CEO at GMG, stated, "I couldn't be happier with the GMG team to get to this point with our battery. We have rebuilt this battery in our weekly sprints from the ground up and developed completely new complex cathode, anode and electrolyte. This will provide a next generation fast charging battery technology currently not available in the world, and we look forward to sending out sample cells to test with partners in early 2026. This technology has many years of development in front of it and will improve as we keep pushing through known issues to improve capacity, voltage and reduce weight."

It is believed by the GMG management that the firm's latest battery innovation will support improving the cathode, anode, electrolyte and overall component weights. This is possible because the technology will be able to surpass 150 Wh/kg when charged in just one hour and achieve over 75 Wh/kg when charged in six minutes.

Figure 4: Current Multi-Layer Battery Pouch Cell

Battery technology readiness level ("BTRL")

The BTRL for the firm's latest G+AI technology has remained at Level 4. The company, currently, is exerting efforts to enhance the electrochemical performance of pouch cells through ongoing experiments in the lab. This is being done with the support of the Battery Innovation Centre, where the company is optimistic about moving the technology up to BTRL levels 7 and 8, as the equipment and manufacturing processes for G+AI batteries. This is considered to be similar to those used in lithium-ion battery production. The firm is highly confident in maintaining its battery cell development timeline, aiming for customer testing in 2026 and small-scale commercial production in 2027, with support from several partners, including BIC.

_0_0.jpg)

Figure 5: Battery Technology Readiness Level (BTRL)

Must read: Key industry individuals share their thoughts on the trending topics

Effective market application & commercialisation

Jack Perkowski, the Chairman and Non-Executive Director of GMG, stated, "I am extremely proud that GMG has progressed its battery to this stage. It is a significant milestone for the Company because the battery technology has so much opportunity in so many applications - especially in commercial vehicles. I look forward to the next updates as GMG makes further progress in the development of its battery technology."

At present, the firm is exploring degrees of potential usage of its latest battery innovation, which is possible by utilising ultra-high power density and a competitive energy density profile. With Rio Tinto, various global companies have shown their confidence and interest in working with the firm's technology in various applications.

Figure 6: Market Applications

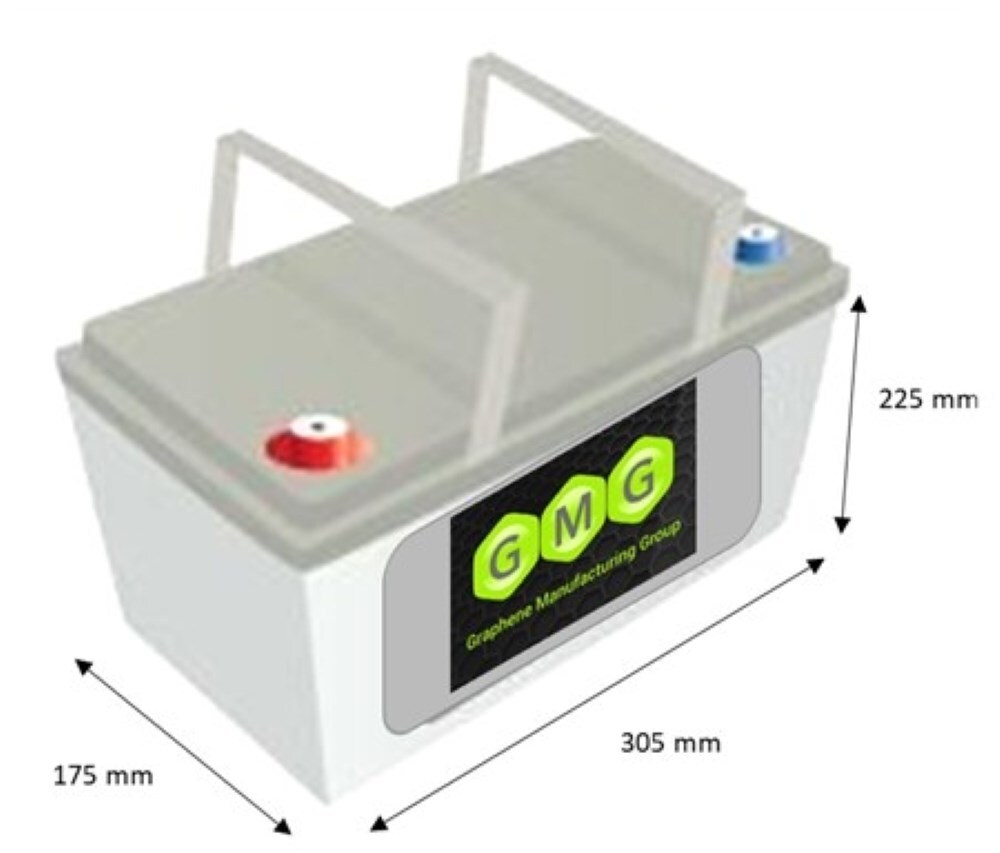

The firm is also looking to switch to a plastic battery pack design where the main aim is to make the battery pouch cells lighter, cheaper and simpler to design compared to traditional metal casings. The firm is confident enough about its battery technology, eliminating the need for a thermal management system or the fire-protection features usually found in lithium-ion battery metal enclosures, making the plastic pack a practical choice.

Figure 7: Expected Battery Pack for G+AIB Pouch Cells

Market review and comparison with LTO batteries

Lithium titanate oxide (LTO) batteries pose a higher price value if compared with the lithium iron phosphate (LFP) and lithium nickel manganese cobalt (LNMC) batteries. The usual go-to choices for electric vehicles and energy storage systems are the LFP and LNMC. When it comes to the firm's latest battery technology, the material and manufacturing costs are expected to be the same or lower than those of standard lithium-ion batteries, which is deemed to be significantly cheaper than what is required for producing LTO batteries.

It has been seen that the LTO batteries' energy density is between 50 and 80 Wh/kg, which are sold globally for various applications, raking in about USD 5.6 billion in sales by 2025. The LTO market is anticipated to grow at a compound annual growth rate of around 10 per cent, potentially hitting an estimated USD 9.0 billion by 2030. Major global players in the LTO battery space include Toshiba, Gree, Microvast and CATL.

Explore- Most accurate data to drive business decisions with 50+ reports across the value chain

Responses