您想继续阅读英文文章还

是切换到中文?

是切换到中文?

THINK ALUMINIUM THINK AL CIRCLE

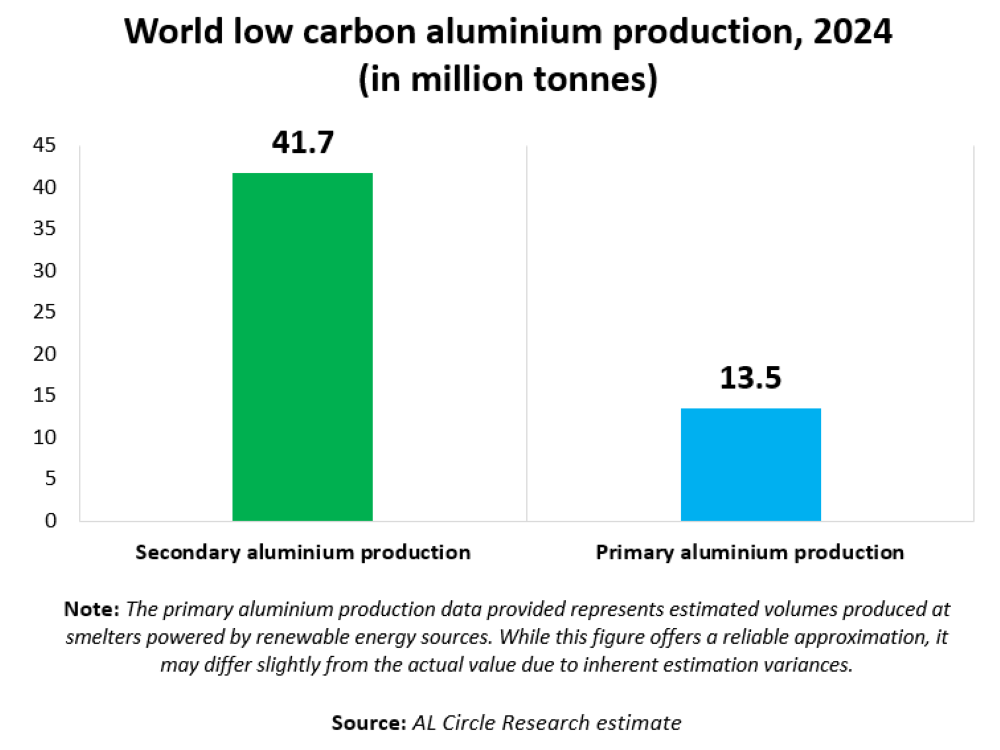

No matter what industry it is, the demand for aluminium is skyrocketing alongside the urge to attain products which are sustainable, recycled and environmentally friendly. Rising demand for aluminium is surging due to the sectoral shift towards reducing GHG emissions. Hence, rapid aluminium usage is done in the renewable energy sector and electric vehicles (EV). For this, China has set their production cap to 45 million tonnes as their initiative to achieve low-carbon production. In 2024, the global low-carbon aluminium production stood at 55.2 million tonnes indicating the rapid shift.

Demand from renewable energy sector

Key features of aluminium, likely corrosion-resistance, durability and lightweight strength, are contributing towards the global demand for the same in the renewable energy sector. The demand is mainly witnessed in building renewable energy platforms like turbines and solar panels.

As per the World Bank study, aluminium is deemed to be the single most widely used metal in solar photovoltaic (PV) applications. Concerning the demand for building solar PV panels and frames, aluminium accounts for more than 85 per cent of the mineral material.

In terms of solar panel frames, the demand for aluminium extrusions is extremely high globally as it aids in improving the solar cells themselves. Additionally, unique reflectivity properties support rapidly growing the overall efficiency of the solar panels. This highly contributes towards the aluminium demand growth globally.

Demand from the EV sector

The energy transition sector is determined to surge the overall demand for aluminium by 37 per cent by 2040. The majority of the demand within the sector is driven by contributions like electric vehicles, solar and the transmission & distribution (T&D).

In the broader scenario, the T&D sector within the energy transition is set to be strong, after which the EV sector comes in. With global electrification at the focus, the development of new transmission infrastructure is urgent, especially in developing countries. With this, the aluminium demand will rise for substitution within certain applications, helping in improving reliability and cost savings.

Moreover, within the grid infrastructure options, the aluminium substitution rate is determined to be positive ~70 per cent for high-voltage transmission lines, ~60 per cent for underground power cables, ~55 per cent for subsea cables and ~65 per cent for microgrids.

Decarbonisation via taxing carbon leakage

Effective carbon leakage prevention techniques are drawn by the European Union's Carbon Border Adjustment Mechanism (CBAM) using their carbon pricing tools. However, CBAM's effectiveness highly depends on both the direct and indirect emissions done during production.

To achieve the CBAM's effectiveness, all the producers need to indulge in low-carbon technologies alongside using green power. However, implementation of tax is one of the key ways to address carbon leakage, there are still more to it.

Using scrap for decarbonisation

The total consumption of the secondary aluminium made from recycled scrap stands at 42 per cent. Utilising this scrap helps reduce energy consumption and emission for production in comparison to the primary aluminium.

With increased use of scrap for making secondary aluminium, the industry can enhance their sustainability goals as well as meet the capacity with the supply demands. In sustainability, aluminium lowers the cradle-to-gate emissions when used in the place of primary aluminium. This shall also increase the proportion of post-consumer scrap and lower the overall emissions.

Technological implications in decarbonisation

Irrespective of the surging demand, aluminium sustainability heavily relies on the shift towards low-carbon production. The introduction of sustainable technologies is poised to replace the current high-emitting ones with varied levels of maturity. For instance, electric boilers, inert anodes and hydrogen calcination poses the potential of creating medium to high impact on the greenhouse gas emissions.

Indirect emissions from the aluminium smelters are caused mainly because they highly rely on fossil fuel energy consumption. By shifting to renewable energy sources like wind and solar, the reduction of these emissions can be achieved with slight challenges towards the intermittent supply.

The majority of the smelters make use of Power Purchase Agreements (PPAs) for securing long-term reliable renewable energy. However, this is highly subjected to challenges like delays in projects and increased cost.

Responses