Earlier this week, Geoff Matthews, Futurist, Future Aluminium Forum Advisory Board Member and Energy Sector Lead for EnPot Ltd, unveiled the first proposed pathway to zero carbon for primary aluminium production at the Aluminium Online Showcase 'Green Technologies' session.

Geoff Matthews said the development of the Pathway was motivated by the International Energy Agency’s June 2020 update for aluminium production.

{alcircleadd}

“The IEA gave the aluminium industry fail mark with ‘more effort needed’, and this promoted us to dive more deeply into what a pathway compatible with the IEA’s Sustainable Development Scenario (SDS) would look like,” said Mathews

He also said, “We wanted to understand what it would mean for the industry in terms of the technological innovation required, the potential roadblocks and cost implications, as well as the most effective allocation of capital. We also wanted to understand what the first steps were for smelters owners globally, as with any journey, they are often the hardest to take.”

Mathews added that in the current course, primary aluminium production is likely to emit 52.7 trillion tonnes of carbon dioxide into the atmosphere during 2020-2050, predominantly due to coal-fired power generation.

He further explained that by 2050 primary aluminium production would be emitting 2.83 trillion tonnes of carbon dioxide per annum, equivalent to over 90 per cent of the CO2 emissions from all of the passenger vehicles in the world today. So, going ahead primary aluminium production will be left as the single consumer responsible for 100 per cent CO2 emissions.

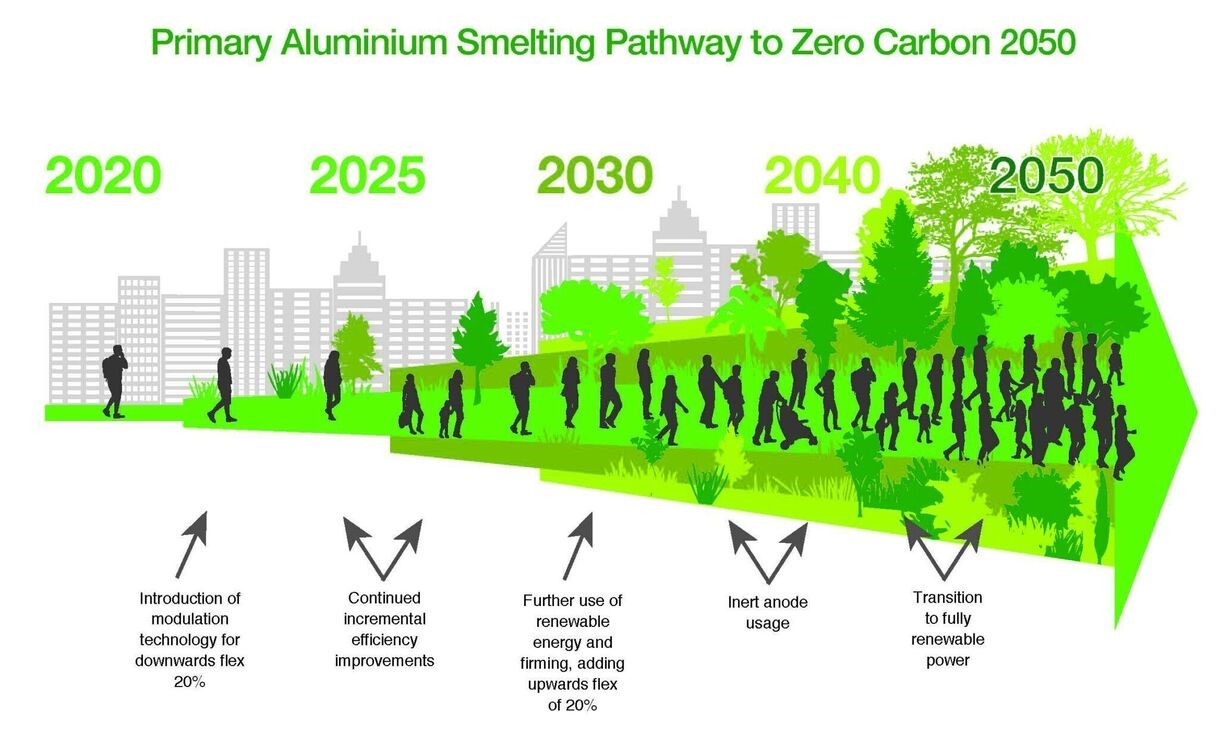

If steps are taken now, the future for aluminium can be completely different as the metal has the potential to be one of the most environmentally friendly materials on the planet. Mathews suggested the only credible pathway to zero emissions for the aluminium industry would be a trifecta of continuing to reduced energy intensity, the adoption of inert anodes, and the shift to using 100 per cent renewably generated power.

The adoption of modern energy modulation technology will reduce the 2050 CO2 trajectory by further 30 per cent. The cost involved is estimated to be around US$50 billion with a return on investment period of around seven years.

The cost of replacing all coal-fired power generation used for aluminium smelting is estimated to be US$131 billion. It’s mammoth but could be off-set by annual operational savings. It has a return on investment period of around 18 years.

Responses