您想继续阅读英文文章还

是切换到中文?

是切换到中文?

THINK ALUMINIUM THINK AL CIRCLE

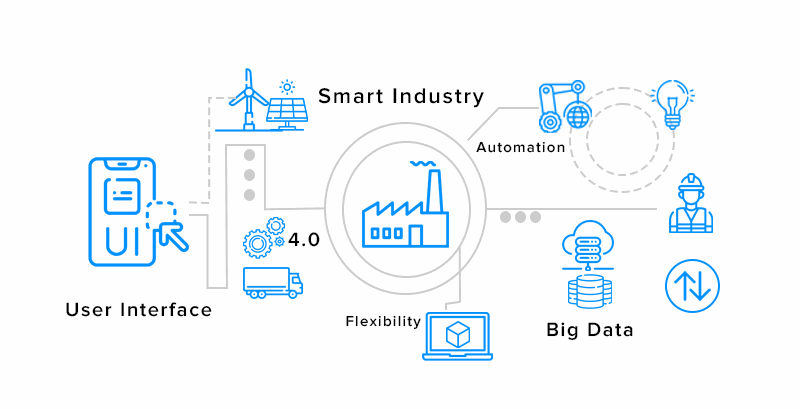

The e-Magazine "ALuminium LeaderSpeak 2024" by AL Circle delves into the development of technology in the aluminium sector. Aluminium, renowned for its versatility and lightweight nature, stands as a cornerstone in numerous industries, owing to its remarkable properties. As we gaze into the future, a multitude of emerging trends and technologies are poised to redefine the landscape of aluminium, ushering in revolutionary applications, and unlocking unprecedented opportunities. When considering Industry 4.0, the aluminium industry might not immediately spring to mind. Nevertheless, cutting-edge technology is swiftly demonstrating its value in assisting companies to maintain resilience amidst a demanding market landscape.

In today's rapidly evolving landscape, technology plays a pivotal role in transforming industries worldwide. Among these, the aluminium sector stands out, undergoing significant shifts propelled by technological advancements. From extraction and manufacturing processes to recycling and energy efficiency, technology plays a crucial role in reshaping the future of aluminium production. With innovative solutions and state-of-the-art tools, the aluminium industry is undergoing a profound transformation, bolstering productivity and sustainability, and opening new avenues for design and application. Take a glimpse into the potential progress facilitated by the Internet of Things (IoT) and its associated technologies:

Smart tools to improve aluminium smelting process

Aluminium smelting, a process involving high temperatures and electrolysis to extract aluminium from its oxide, is highly sensitive to errors. To mitigate risks and enhance efficiency, companies are turning to digital solutions. Even a slight 1% improvement in productivity could translate to global savings of $970 million annually in production costs. Technology investments offer insights through data analytics, providing crucial details on temperature and chemistry. This empowers plant managers to optimise operations, minimising waste, and expenses proactively. Enhanced knowledge of operations enables producers to effectively respond to demand fluctuations by scaling production accordingly and reducing the likelihood of costly unexpected events.

Data-driven approach improves sustainability

Sustainability has evolved into a key differentiator for aluminium producers, with power consumption emerging as a pivotal aspect of their eco-friendly practices. It is possible for producers to accurately track their electricity usage using IoT sensors over time, facilitating targeted improvements and highlighting opportunities for optimisation. Producers can use a data analytics platform to visualise their electricity consumption trends, assess the impact of various production processes, and articulate precise sustainability enhancements to stakeholders.

Furthermore, recent research suggests that implementing a wireless monitoring system can mitigate anode effects, a phenomenon where excessive voltage in smelting pots leads to gas emissions. This system detects potential issues well in advance, offering valuable lead time for intervention. Preliminary findings from such initiatives indicate the potential to significantly reduce greenhouse gas emissions by up to 0.8 tonnes of carbon dioxide per tonne of aluminium produced, underscoring the substantial environmental benefits achievable through proactive monitoring and intervention.

Leveraging Industry 4.0 advancements for enhanced competitiveness

While sustainability remains a pivotal focus for aluminium producers' success, it's not their sole concern. The COVID pandemic significantly impacted the sector, particularly in the United States and Europe, leading to a temporary decline in production due to decreased demand. Despite this setback, global forecasts indicate significant growth in the sector in the short and long term.

The technical experts advocated leveraging industrial technologies to stimulate recovery in response to these challenges. For instance, integrating robots could mitigate the need for manual labour in plants, assuming risky tasks and thus improving workforce retention. Additionally, implementing connected sensors enables seamless machine communication, optimising workflow efficiency. By harnessing data from Industry 4.0 equipment, companies can scrutinise their processes and make informed decisions to enhance productivity.

The aluminium companies' thorough investment in IoT and related technologies offers real-time access to comprehensive data from shop floors and production units via dashboards. The company's technical team can also leverage historical data to predict equipment failures and process deviations. This proactive approach enhances uptime, facilitates proactive maintenance, and achieves high operational production levels.

Mining made safer and more productive with digital technology

IoT technology is more comprehensive than aluminium production's smelting and post-smelting stages. Take Rio Tinto, for instance. This mining giant has implemented a digital communication system in its operations hub. This system is designed to seamlessly link with the company's disaster recovery centre, enabling continuous safety and production monitoring, even during emergencies.

Moreover, IoT solutions are revolutionising mining operations themselves. A mine equipped with over 250 wireless access points spread across 31 miles of tunnels. This level of connectivity has transformed productivity, as evidenced by a fourfold increase in output at a gold mine. IoT has demonstrated its potential to enhance efficiency across the mining sector, including aluminium production, by tracking miners and vehicles and introducing automation into safety and operational procedures.

Through connected sensors, mining environments can be monitored in real time, issuing warnings when conditions deteriorate. Additionally, IoT empowers site managers to ensure adherence to safety protocols and regulatory compliance, minimising accidents, and maximising operational efficiency. This technology promises to elevate safety standards and productivity in the aluminium industry significantly.

Industry 4.0 presents promising prospects for the aluminium sector

The use of connected technologies in aluminium smelting holds vast potential, whether for enhancing operational efficiency or promoting sustainability practices. The landscape offers numerous avenues for integrating smart solutions into manufacturing processes. As more organisations embrace technology-driven approaches and witness the benefits firsthand, the momentum towards widespread adoption is poised to surge.

Conclusion

The ongoing evolution of the Fourth Industrial Revolution, also known as Industry 4.0, entails the continuous transformation of industries through the adoption of cutting-edge smart technologies. Within this paradigm, the aluminium industry is experiencing noteworthy advancements in automation, remote assistance, mobility, and sophisticated control systems. This technological progress presents new avenues for the aluminium sector to confront upcoming challenges, particularly those stemming from climate change. Most prominent among these challenges is the imperative to enhance energy management, compelling smelters to exhibit greater adaptability in modulating their power usage.

Responses