Foundries operate in extreme environments marked by high temperatures and large, hard-to-reach equipment. Handling molten metal like aluminium in such conditions demands exceptional resilience and adaptability from both people and machines. While several quality control systems for molten aluminium already exist, they tend to be costly, require specialised expertise, and are time-intensive, limiting their use to occasional spot checks.

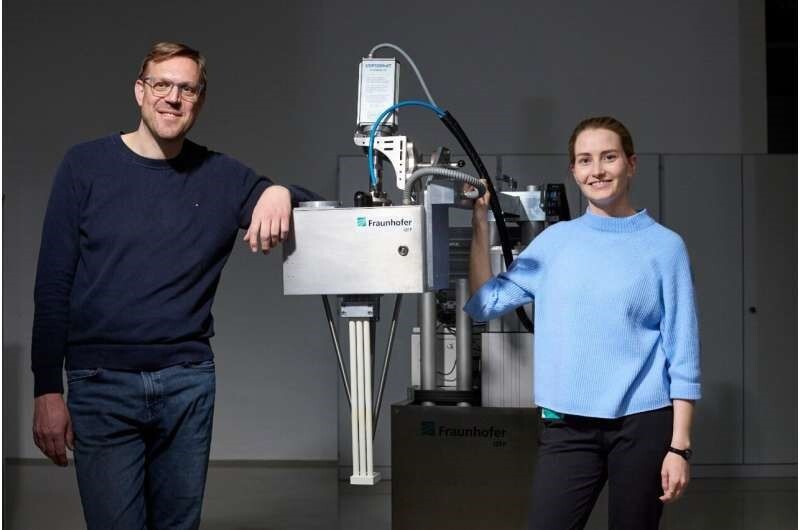

This need sparked the idea at Fraunhofer IZFP to develop a mobile, ultrasound-based measurement system specifically for molten aluminium. The team has also bagged the prestigious Joseph von Fraunhofer Prize 2025 for their groundbreaking development.

Ultrasound-based measuring system for aluminium production

Recognising these challenges, a team of researchers at Fraunhofer IZFP set out to develop an innovative measuring system for the aluminium industry designed to detect impurities in molten metal and support quality assurance during production.

The result was the launch of the AloX project, which combined "aluminium melt" and "oxide inclusions." An innovative ultrasound-based system that rapidly and accurately detects inclusions in molten aluminium, offering a cost-effective solution for quality control.

From lightweight automotive alloys to the use of aluminium in solar panels, sustainable metal is the second most widely used metal after steel and plays a vital role in achieving climate neutrality, thanks to its application in lightweight construction and its energy-efficient recyclability. Maintaining its production quality is essential as a key contributor to the circular economy.

Also Read: Study highlights eco-friendly ways to use nickel-aluminium-bronze chip powders for Directed Energy Deposition

"The purity of the molten metal, whose temperature ranges from 600 to 800 degrees Celsius, is hugely important to the final product later on. For example, any ceramic particles that may be present in the melt don't liquefy until they get to a temperature of 2,000 degrees or more, and they remain in the finished component as inclusions if they aren't deliberately removed. This can lead to cracks and holes, and thus, in the worst case, to component failure," said Thomas Waschkies, Chief Scientist for Sensor Physics at Fraunhofer IZFP.

Overcoming challenges

The primary challenge in developing the system was adapting it to the extreme conditions found in industrial foundries. Molten aluminium generates intense heat that impacts the measuring system and its supporting structure, and its highly corrosive nature poses an additional risk to metal components.

Collaborating closely with industry partners, the team successfully created an initial prototype. This prototype includes a mobile measuring trolley equipped with specially designed ultrasonic waveguides, integrated cooling, and a custom software program featuring a patented analysis algorithm. The system also incorporates a patented mechanism for replacing the titanium ultrasonic waveguides.

The team is now advancing the development of AloX 2.0, an improved version of the original system. One aspect remains unchanged: nearly every component has been developed internally at Fraunhofer IZFP. "From the ultrasonic sensors and analysis software to the electronics and housing mechanics, AloX is a complete solution built entirely in-house," notes Mross.

The next phase involves transitioning the system into widespread industrial use, starting with aluminium production. However, the technology also holds promise for broader applications, including quality control in other molten metals and even in sectors like adhesives and food manufacturing.

Also Read: ALMAC and AR Aluminum scale up extrusion capabilities with $7.5M additional investment

Image Source: Fraunhofer IZFP

Responses