Since 2007 and the introduction of Amelios, Fives’ Aluminium division has developed a comprehensive range of digital solutions to enhance the productivity of smelters and achieve greener aluminium production.

Being a worldwide leading solution provider for Green Anode Plant, Anode Baking Furnace equipment, Anode Rodding Shop, Fume & Gas Treatment plant, Potline cranes, Pot equipment, and thanks to the combined expertise of Fives Solios and Fives ECL, Fives sets-up a cross-organizational and transdisciplinary team to further develop digital solutions.

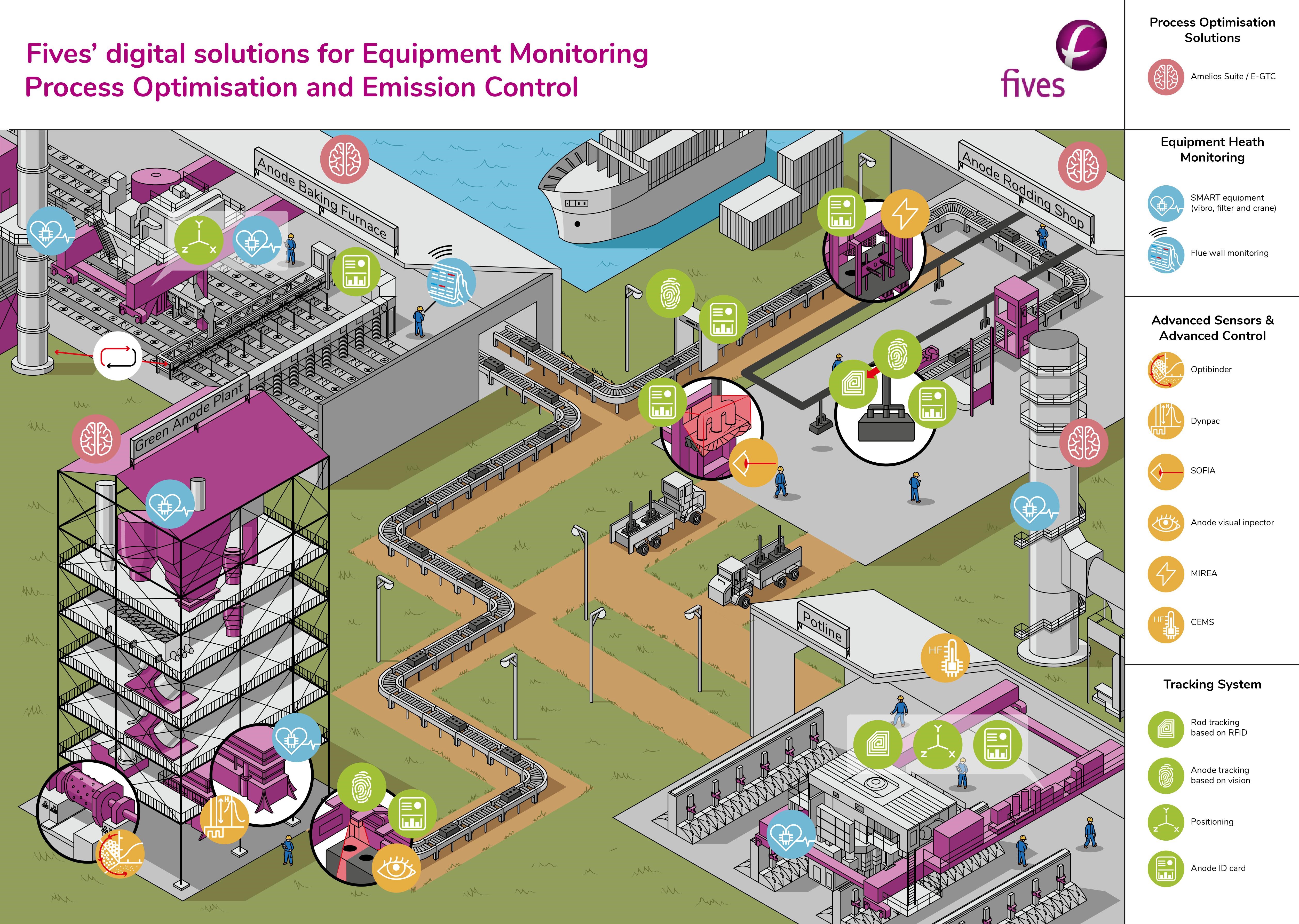

As of today, Fives’ digital portfolio consists of more than 20 solutions that can be used independently or interconnected to act on Equipment Health Monitoring, Process Optimization and Emission Control.

Equipment Health Monitoring – SMART solutions

SMART solutions (e.g. SMARTCrane, SMARTFilter, SMARTVibro, …) consist of software solutions plugged in existing equipment for real-time and remote monitoring. The purpose of the SMART solutions is to increase the availability and reliability of the equipment and maximize the Overall Operations Effectiveness (O.E.E.)

SMART solutions aim to enhance smelters’ operations, maintenance and process by providing a new equipment experience with indicators, dashboards and recommended actions to anticipate fragilities and drifts.

Process Optimization – Amelios Suite

Based on advanced process monitoring & Amelios data analytics software, the Amelios Suite for Green Anode Plant, Anode Baking Furnace and Rodding Shop includes:

The purpose of the Amelios Suite is to lower the Net Carbon Consumption (NCC), consequently the CO2 emissions as well as the consumption of raw material and energy and ultimately to increase the production of aluminium.

Amelios Suite allows to:

Process Optimization – e-GTC

Based on Continuous Emission Monitoring System (CEMS) and advanced process control, the Fives' e-GTC allows for enhancing smelter environmental performance and reducing operating costs through constant monitoring of emissions and equipment.

The above-mentioned solutions have been validated by proof of concept or are already implemented in smelters worldwide with proven track records (e.g. SMARTCrane, Amelios Suite for Green Anode Plant, SOFIA, MIREA…). Additionally, the whole Amelios Suite has been labelled by the SOLAR IMPULSE FOUNDATION in 2021, and the Anode Tracking System based on Vision has been awarded by Light Metal Community (TMS) in 2020, and some solutions are patented.

With more than 660 employees worldwide based in multiple locations across the globe, the Aluminium division of Fives has the ability to support smelters on the definition and the implementation of their digital roadmap locally.

Please visit our new website for the latest information on our digital solutions and to request a tailor-made presentation to suit your needs.

Responses