The German metal components manufacturer Fischer Group has selected the industrial enterprise active in the sheet metal forming AP&T’s solution for hot forming of high-strength aluminium parts.

The outstanding technology is capable of delivering extremely rational and cost-effective production of complexly designed components of various aluminium alloys (6000 and 7000).

High-strength aluminium outperforms conventional sheet metal and results in a 40% reduction in weight of the components without compromising strength. This also develops an increase in the usage of this type of materials in cars, jets and other applications for reducing energy consumption and increasing safety.

Hans-Peter Fischer, CEO of Fischer Group, said: “We have chosen AP&T as a partner for this innovation due to their long experience with the technology itself and their outstanding expertise in automation and press building. In addition, we are very pleased with the modular system which allows us to adapt line output to increases in required capacity. Finally, the servo-hydraulic press is a step forward in achieving energy-efficient production to optimize the CO2 footprint of forming technologies.”

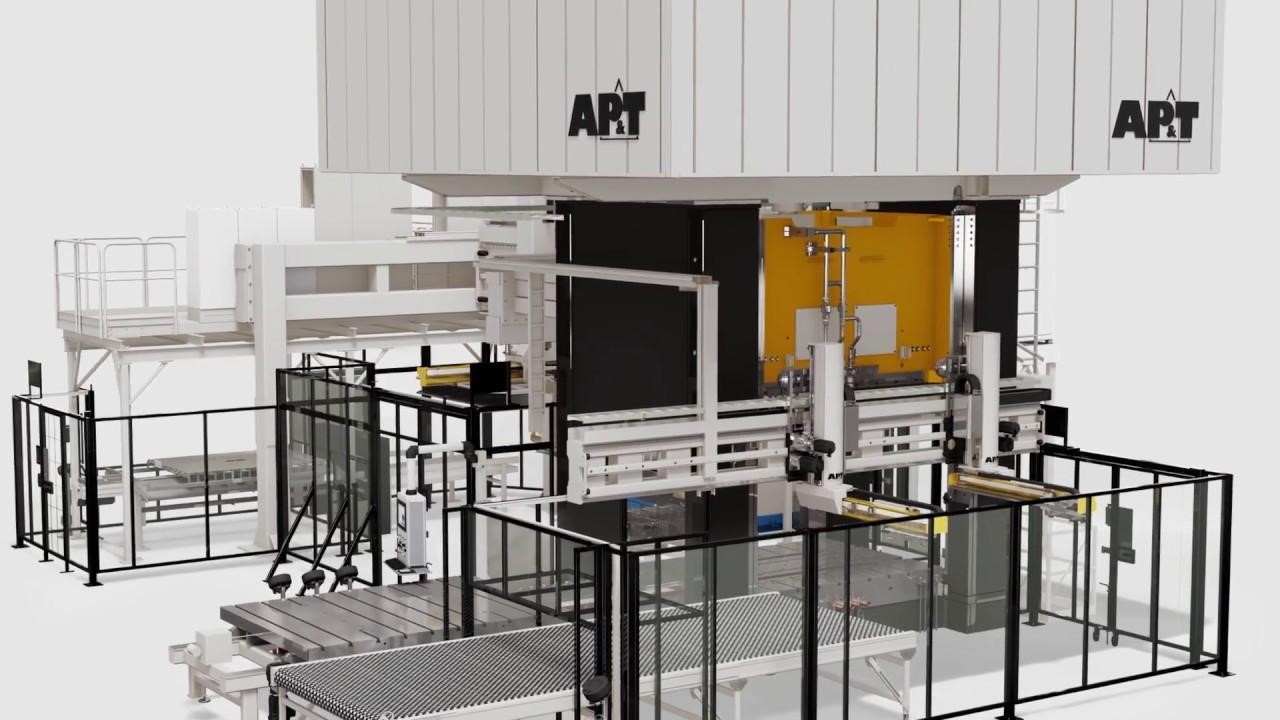

During this summer at Fischer Group’s facility in Achern, southern Germany a complete fully automatic high-strength aluminium hot-forming production line from AP&T is planned to become commercially operational.

The equipment comprises AP&T’s servo hydraulic press, which capacitates high-precision forming control throughout the press cycle. The servo-hydraulic press is also substantially high energy-efficient than conventional hydraulic presses.

Christian Koroschetz, Chief Sales Officer at AP&T, said: “To start with, the line will be used for small and medium-sized manufacturing volumes, but thanks to the flexibility of our modular system of standard components, it will be possible to expand the line and scale up production at pace with demand.”

AP&T’s solution for hot forming of high-strength aluminium has bagged several prestigious awards, including the Altair Enlighten Award and the SIQ Quality Innovation Award.

Responses