Belonging from Kazakhstan, Eurasian Resources Group (ERG) has collaborated with a German organisation, ThyssenKrupp, to develop hybrid filter technology for its plants. In December 2021, ERG signed a contract with ThyssenKrupp to invest US$44 million or 19 billion tenge for developing four electric filters in sintering furnaces at ERG’s Pavlodar Alumina plant.

Eurasian Resources Group (ERG) is attempting to decarbonise its projects utilising green hydrogen and renewable resources, as was cleared by the chairman, Board of Directors, Alexander Machkevitch.

“We are exploring replacing fossil fuel oil in calcination kilns with green hydrogen, which can eliminate 100 per cent of direct greenhouse gas emissions,” Machkevitch notified.

He also added that ERG plans to develop a renewable capacity of 6 gigawatts by properly utilising wind and solar plants.

ERG declared that Kazakhstan could meet its climate goals by lowering the carbon emissions rate. The country has targeted to cut GHG emissions by 1.5 per cent each year between 2022 and 2025 to reach 15 per cent lower emissions by 2030. ERG has 40 projects to its name, and this partnership with ThyssenKrupp will have a constructive outcome in the future.

ERG plans to prevent particulate two-fold emissions and omit at least one-third of total water consumption by 2030, ultimately eliminating CO2 emissions weighing 2 million tonnes each year. ERG will have to invest a complete sum of US$1.6 billion, to accomplish the entire drill. By 2060, Kazakhstan wishes to become carbon neutral.

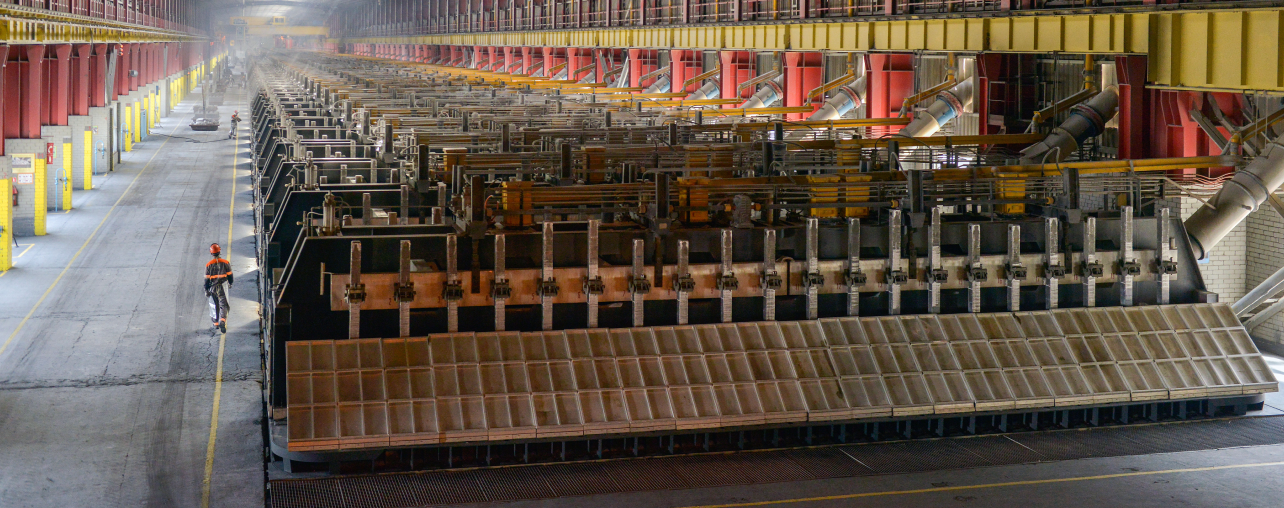

ERG’s JSC Pavlodar Aluminium Smelter has a capacity of 250ktpa where primary unalloyed commercial grade aluminium in 20kg standard ingot shape is blended to produce refined aluminium, electrically constructive products and aluminium alloys.

Responses