Epsilon Carbon, India's foremost manufacturer of coal tar derivatives, as well as the nation's only backwards-integrated manufacturer of raw material, has agreed to collaborate with edible oil refiner Sri Anagha Refineries to construct molten pitch storage tanks at the refiner's premises in Mangalore on India's western coast. Storage tanks capable of holding 10,000 metric tons will be erected at the facility.

The Mangalore Port is the seventh-largest port in the country and it is a place where some of the key primary commodities are imported as well as exported.

The carbon company exemplified, “Since the port had a draft of 14 metres, it allowed vessels up to DWT of 100,000 MT to berth, and thus the facility would help Epsilon to scale up exports.”

Epsilon further added, “Through this facility, being a qualified supplier, the company plans to cater to the global aluminium smelters which are mostly served by China.”

Saiprasad Jadhav, the CEO at Epsilon Carbon, said, “We aim to produce 300,000 tonnes of coal tar pitch every year and with the metal upcycle, a lot of global aluminium customers have been approaching us to cater to them. We took this decision after numerous discussions with our customers and believe this facility will help reduce the transit time for our customers.”

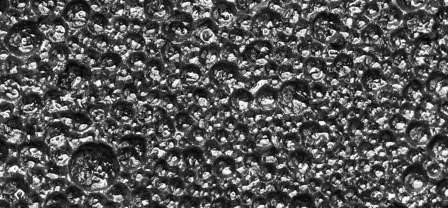

The primary product from the distillation of coal tar is carbon pitch. It is a vital raw material in the production process of aluminium. It is utilized as a binding agent in the production of carbon anodes for aluminium smelters.

Aluminium smelting is an electro-metallurgical process, where refined bauxite ore called alumina is combined with electricity in a reduction cell or pot with a molten electrolyte called cryolite. While DC flows from a carbon anode into the cryolite, separating oxygen atoms from the alumina to produce molten aluminium and carbon dioxide. Carbon Pitch bestows the strength, density and electrical conductivity characteristics of the anode (and cathode) necessary for the efficient conversion of powder alumina to liquid aluminium.

Responses