With the development of the pivot mount, EAW not only has a history spanning more than a century but has also raised the bar for the crucial relationship between optics and firearms. Even though EAW already has a titanium 3D printed scope mount available, the German manufacturer of high-quality scope mounts is now expanding into new markets with the lightweight aluminium mount created utilising the 3D print technology.

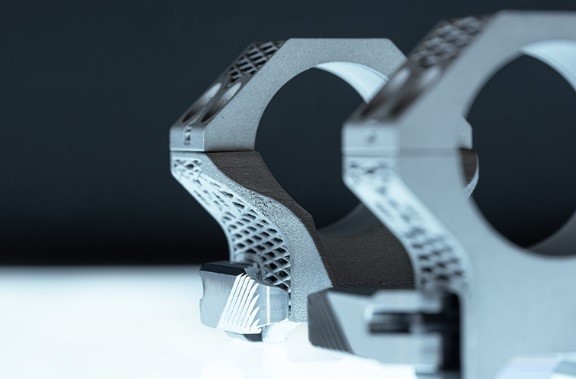

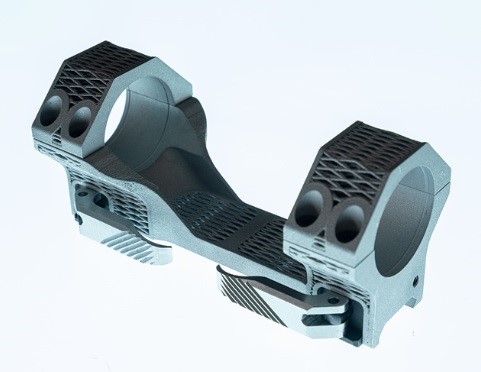

The new EAW 3D mounts instantly catch the attention of seasoned rifle shooters who have seen it all. The German firm utilises every design-related feature of the 3D printers made accessible by CAD technology. EAW employs the "Direct Metal Laser Melting" method of 3D fabrication (DMLS). Here, a laser melts metal powder (aluminium, steel, titanium) layer by layer by the CAD model.

Since DMLS has grown significantly in recent years, that series may also be produced profitably. This method has been used for a very long time to manufacture silencers to create unique inner structures. However, the entire mount was not built utilising the metal printing technique.

The 3D printed mount assembly described here has a 30- or 34-mm ring diameter in two heights made of aluminium or titanium alloy and a quick-release lever mechanism. The mounts may be ordered in natural aluminium, black anodised, RAL 8000, or with custom coatings.

Responses