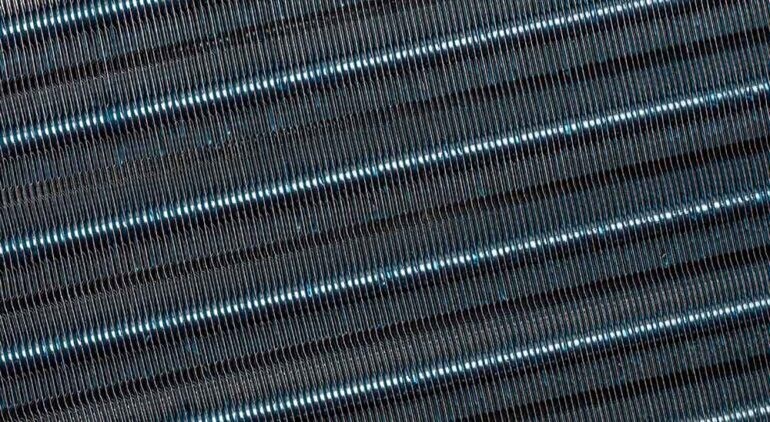

Daikin plans to manufacture air-conditioner heat exchangers from recycled aluminium after refining a horizontal-recycling process. Traditionally, these components rely on high-purity aluminium for ease of processing. By contrast, fins recovered from used heat exchangers contain copper and other impurities, so they’ve typically been downcycled into products such as automobile engine parts, making it difficult to restore the metal to its original grade.

Working with recycling specialist Nippon Magnetic Dressing and global aluminium producer UACJ, Daikin is developing a closed-loop approach to resource circulation through horizontal recycling, where the end use remains the same before and after recycling.

By sharpening aluminium–copper sorting and enhancing aluminium’s press-formability, the project has reportedly produced heat exchangers on a standard line using fins made from recycled aluminium. Producing recycled aluminium can cut CO₂ emissions by up to 97 per cent versus primary metal.

Get industry insights from - ALuminium in Packaging: Consumer Trends and Market Dynamics

Recycler Nippon Magnetic Dressing developed advanced separation technology, lowering copper content from about 3 per cent to under 0.1 per cent. UACJ then created aluminium with improved press-formability, crucial when trace copper and other impurities are present. Using this material, Daikin successfully press-formed the fin and assembled the heat exchangers.

Daikin says it is now moving toward mass production, focusing on used heat exchangers discarded as industrial waste from its factories and after-sales service operations.

Responses