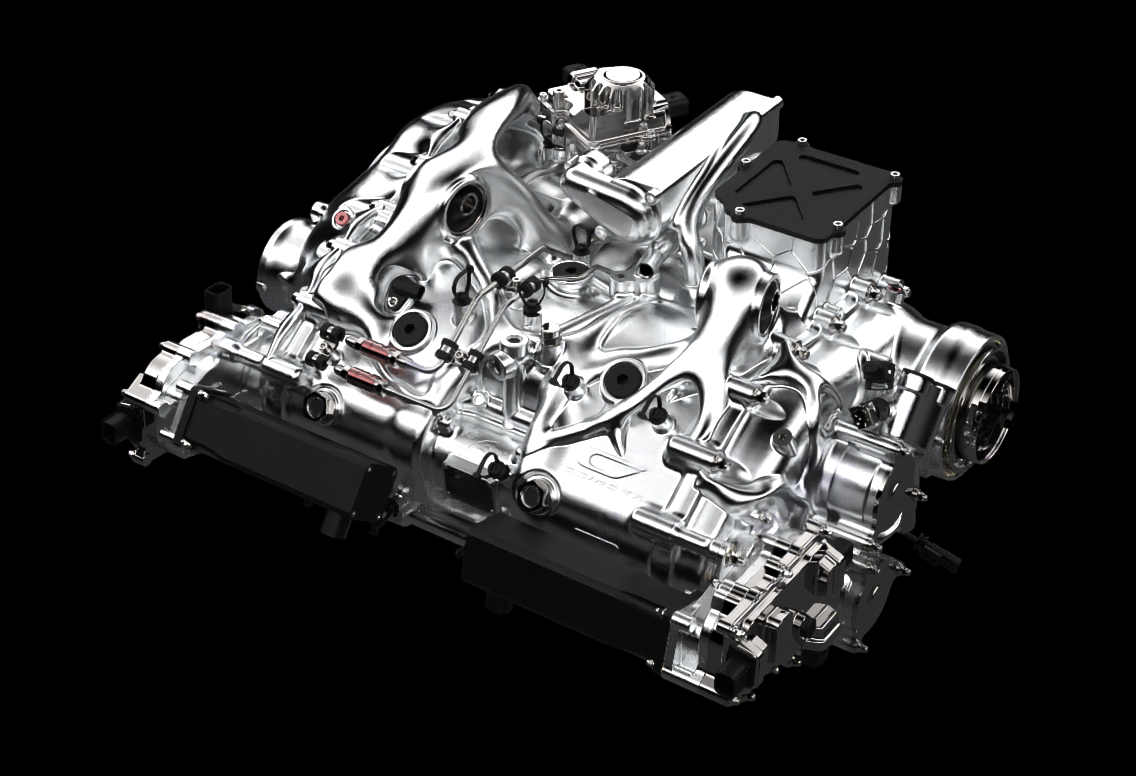

Czinger Vehicles Inc., a Los Angeles-based automobile manufacturer of hybrid sports cars, launched a 3D printed automotive gearbox case which the company claimed as the world’s first. In collaboration with UK automotive engineering firm Xtrac, Czinger used topology optimization software to design the gearbox case and printed it in a proprietary aluminium alloy.

Xtrac is specialized in designing gearboxes for race cars, which makes the company an obvious choice for manufacturing fuel-efficient luxury hypercars. The main advantage of 3D printing a gearbox case is that it requires no tooling, besides reducing gearbox case’s mass and complex geometry.

Topology optimization software is combined with AI-driven generative design and its use is often found in additive manufacturing. The software is used to speed up the design phase and maximize certain engineering attributes. Czinger’s parent company Divergent Technologies developed its own in-house topology optimization software, one of the integral components to the DAPS platform.

In a press release about the first 3D printed gearbox case, Lukas Czinger, the co-founder and senior VP of operations at Czinger Vehicles, commented, “We are proud to team Czinger’s world-class engineers with those at Xtrac; together, we have developed an incredible, industry first, gearbox that is truly at the pinnacle of performance. We can’t wait to shatter more track records as we utilize this system in the 21C.” The CEO of Xtrac, Adrian Moore, said, “What our Xtrac engineers have accomplished in tandem with Czinger and Divergent is groundbreaking. Xtrac is pleased to be at the forefront of cutting-edge gearbox manufacturing by creating these 3D printed casings. It has been extremely interesting and very stimulating for our engineers working closely together to bring this cutting edge innovation to life.”

Czinger said Divergent Technologies received a $100 million investment in 2022-end from Swedish software giant Hexagon AB. Earlier, Divergent received $240 million in financing and investment in 2022 alone.

Responses