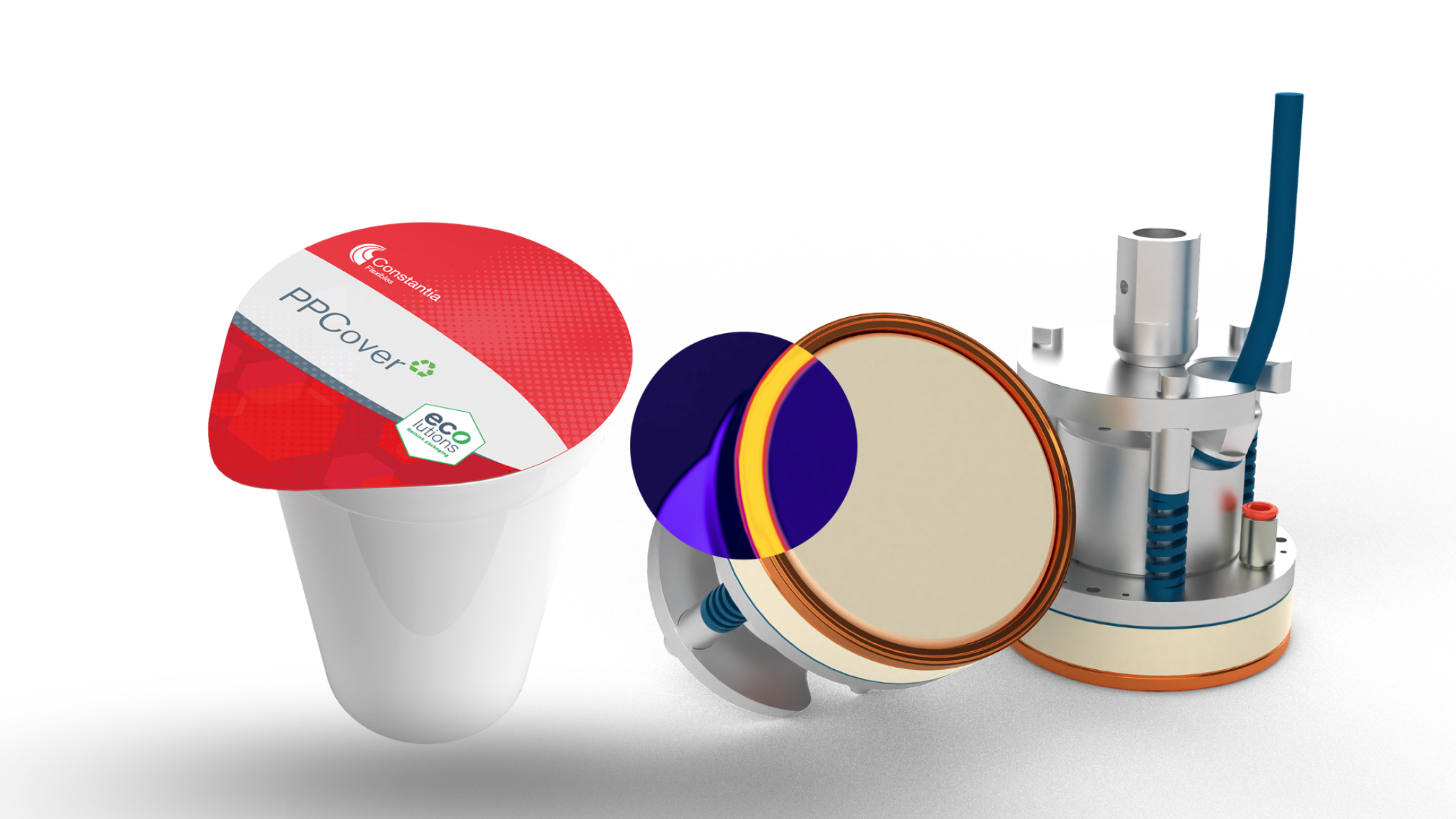

Constantia Flexibles and Watttron have developed a high-end sealing solution that allows polypropylene (PP) and aluminium lids to be sealed on the PP cups using the same system.

The innovation is built on Constantia Flexibles’ PPCover, a mono-material PP lidding solution. The primary obstacle was adapting it to existing sealing machines because it might lead to inconsistencies. Also, there is an ongoing pressure to maintain consistent, high-quality seals across various lid materials, without any deformation.

Here’s how the innovation surpasses traditional seals

Conventional sealing systems usually cover the entire sealing head, which often leads to excessive heat exposure and issues like lid curling. While these are not too common, these risks led Constantia Flexibles to explore a more precise and adaptable method to improve reliability and material compatibility.

Also Read: Drip Water saves 80K aluminium bottles from waste

Watttron’s ring-heating offers a precise alternative that requires heat application only at the exterior sealing ring. It minimises thermal stress on the lid material while being energy efficient.

The system promises rapid temperature control and optimum temperature level maintenance, which is up to 20°C adjustment precision. The new sealing solution ensures stable sealing performance and enables the equipment to be safely powered down when there is no production. It will contribute to up to 50 per cent of energy savings compared with conventional systems.

Effortless production and improved inspection

The new sealing solution will no longer need separate machines or setups for different lid materials, further reducing equipment complexity and streamlining production.

Additionally, the system integrates 100% inspection capabilities, allowing for real-time detection and easy removal of defective cups, ensuring consistent product quality.

Also Read: 2025: US tariffs & economic challenges drive 4% drop in aluminium aerosol can deliveries to America

Responses