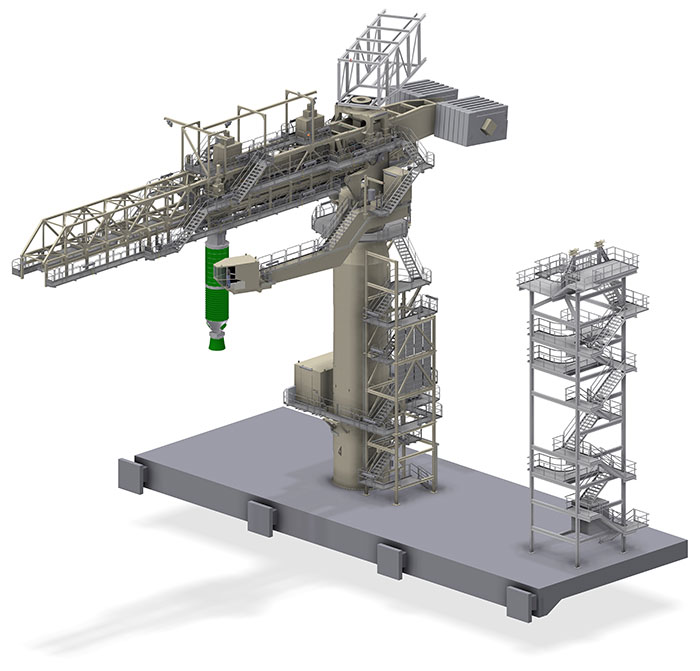

Cleveland Cascades recently commissioned one of the latest Cascade chutes in partnership with Reel Alesa for loading of alumina.

The company was looking for a flexible and transferrable solution that could remove the alumina product from 4 tankers into a hopper, and then along a screw conveyor. They wanted a dust-free loading of alumina which was fulfilled by Cleveland’s unique Cascade chute. The 20 m chute was installed in the ship loader in order to effectively handle alumina at rates up to 275 metric tph.

The Cascade chute uses an auto raise and auto lower system for pile building and with the help of these features combined, it can effectively load the alumina product and distributed it effectively to fill the vessel.

{googleAdsense}

The Cascade chute operations allow the alumina to be loaded in mass flow at a low speed, but high volume handling the aggressive nature of the material effectively. The Cascade chute has been proven effective for loading without dust emissions generation, and degradation of material particles. These two issues were the main concerns which were behind the project which finally resulted in the selection of the Cascade chute from Cleveland.

Responses