ChemX Materials has officially verified the noteworthy 4N (99.99 per cent) purity outcomes obtained from its wholly-owned high-purity alumina "micro-plant" located in the southern suburbs of Perth, Western Australia. The results were determined across an astonishing range of 66 elements and represented a significant milestone for the company - reached just a year after launching its HPA plant - on its journey to 5N (99.999%) purity.

“This is a proud day for CMX shareholders and the team. Today’s breakthrough validates the disruptive nature of the HiPurA® process and ChemX views the ability to achieve bespoke high purity (4N) outcomes in a locally-based, scalable, modular format may be a game-changer for gigafactory feedstock management. Importantly, data obtained during the optimisation of the Micro Plant will be included in the current Pilot Plant (design) which will produce sufficient sample volumes for global customer qualification,” said ChemX Materials chief executive officer Peter Lee.

{alcircleadd}

Most importantly, attaining the 4N quality certification with its "HiPurA" method implies ChemX-generated material with fewer than 100 parts per million impurities, the minimum purity level necessary for testing and qualification in the global battery separator industry.

The company stated, "sustainably producing a growing range of ultra-high purity aluminium oxides, hydroxides, nitrates and sulphates for a wide range of high-technology industries including LED lighting, synthetic sapphire, semiconductors and lithium-ion battery markets – at world-leading purity levels and at a dramatically lower-carbon profile".

The purity level achieved in 4N falls short of the highly sought-after benchmark of 5N. However, even when operating at a market capitalisation of 4N, firms within the same industry sector, such as Alpha HPA, have successfully established a dominant position. The market capitalisation of Alpha is currently in the vicinity of $700 million, whereas ChemX's market capitalisation stands at approximately $4.56 million.

The former validated its 4N results in 2018 after assays from the company's world-first solvent extraction test run employing its "HPA First" technology were returned. Alpha intends to demonstrate its technological capabilities by implementing its project within the Gladstone State Development Area in Queensland.

Yesterday, the firm made public its agreement with the Queensland Critical Minerals and Battery Technology Fund (QCMBTF) trustee regarding the essential conditions for project funding. This funding, amounting to a maximum of $30 million, aims to expedite the implementation of an initial batch of 50 sapphire growing units. High-purity aluminium oxide (alumina), known as HPA, is crucial in several applications. It serves as a separator layer in batteries and plays a vital role in manufacturing synthetic sapphire and LED lights.

The primary driver behind the global demand for high-purity alumina (HPA) is the swift adoption of lithium-ion batteries (LiB) as the worldwide community shifts towards renewable energy sources. The market value of high-purity alumina (HPA) is significantly influenced by its quality, with particular emphasis on the composition of the final alumina product.

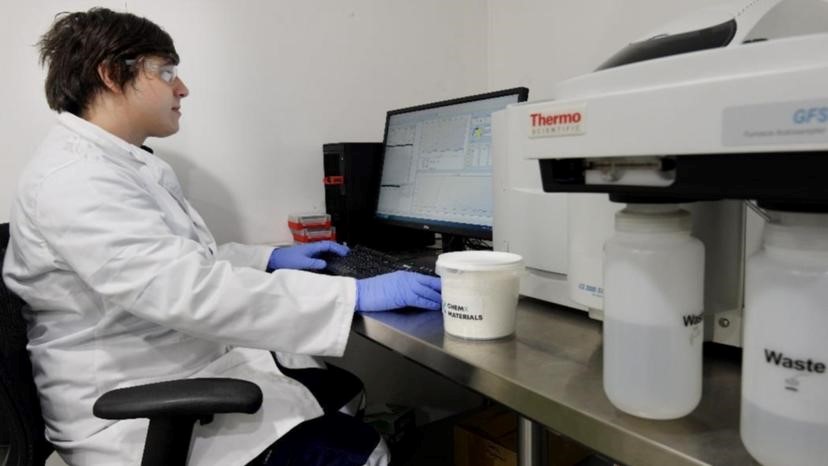

ChemX claims it is currently striving to ensure the repeatability of the 4N result through ongoing plant optimisation so that the process may be scaled up to pilot plant status. It only recently completed its integrated HPA plant to scale its HiPurA flowsheet from laboratory to continuous operation. The HiPurA process is described by management as a disruptive flowsheet that converts aluminous chemical feedstocks to HPA by selective refining. It eventually hopes to provide 4N-grade and 5N HPA products for the electric vehicle battery separator and synthetic sapphire markets, as well as LEDs, semiconductors, and optical lenses.

According to ChemX, the World Intellectual Property Organisation (WIPO) recently released an international preliminary assessment on the patentability of the HiPurA process, concluding that it met the standards for novelty, inventive step, and industrial applicability. A worldwide patent application is in the works. Meanwhile, the company is making additional strategic investments in high-purity analytical equipment and the resources required to help accelerate process repeatability and optimisation.

Responses