On the journey to sustainable manufacturing, Stormtech, a pioneer in architectural drainage solutions, has taken a significant step by integrating Capral Aluminium's LocAl® Super Green aluminium into its Wave Grate product. The initiative was announced in Australia as part of the company's ongoing commitment to reduce environmental impact through low-carbon material choices and responsible design practices.

Image source: capral

Capral’s LocAl® Super Green aluminium offers a notably low carbon footprint of just 4kg CO₂e per kilogram, roughly three times lower than the global average. Using such aluminium ensures the Wave Grate maintains its premium performance while dramatically lowering its embodied carbon footprint.

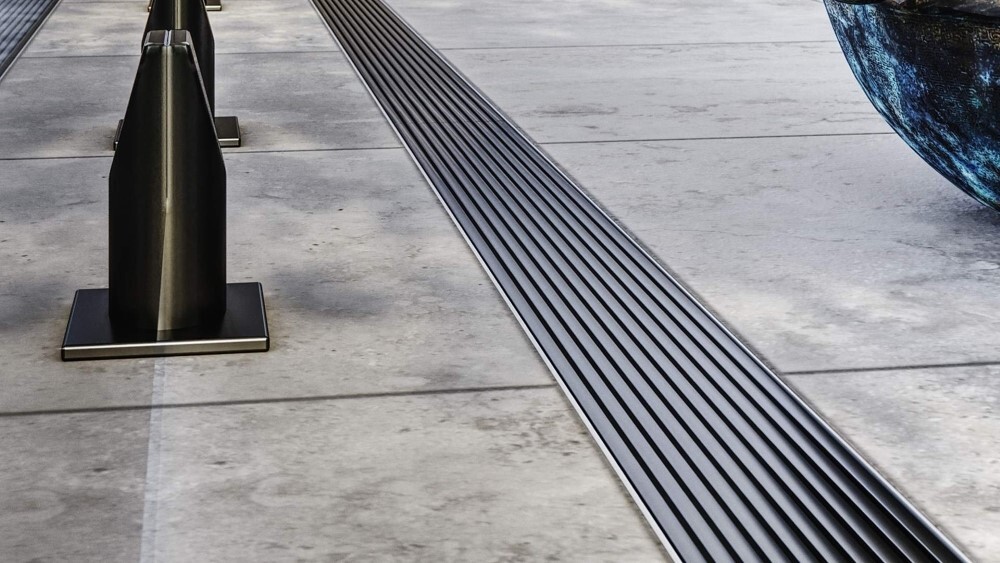

The Wave Grate itself is known for its sleek linear profile and efficient water management. Its latest version now integrates LocAl® Super Green aluminium, strengthening Stormtech’s sustainability credentials. The company’s broader environmental strategy also includes using stainless steel with over 90% recycled content and a carbon footprint 75% lower than global averages.

The aluminium used is supplied under Capral’s LocAl® product range, launched in 2022. Both LocAl® Green and LocAl® Super Green variants are certified under the Aluminium Stewardship Initiative (ASI), ensuring traceability and accountability in sourcing and production. These certifications support manufacturers like Stormtech in meeting the rising demand for verifiable low-carbon materials.

Commenting on the collaboration, Troy Creighton, Managing Director at Stormtech, said, “At Stormtech, we’re always looking for ways to push the boundaries of sustainable design. The choice to use Capral’s LocAl® Super Green aluminium in our Wave Grate was driven by our desire to reduce environmental impact without compromising on performance or design integrity.”

Capral, Australia’s largest aluminium extruder and distributor, views the partnership as an example of how local manufacturing can support a greener future. “As demand grows for sustainable materials, manufacturers must have access to certified low-carbon aluminium,” said Luke Hawkins, Divisional General Manager Industrial and Supply Chain at Capral.

In addition to its work with Stormtech, Capral is also playing a critical role in major infrastructure projects such as Project EnergyConnect. As part of this ambitious interconnector development led by PLP Australia, Capral is supplying aluminium busbars, another testament to its capacity to provide high-quality, locally manufactured aluminium solutions for both sustainable design and national energy initiatives.

Capral’s participation in the Australian Made Campaign further underscores its support for domestic manufacturing and sustainable supply chains. All Capral extrusions are made in Australia, ensuring local customers benefit from high-quality, responsibly sourced materials.

These growing initiatives and project integrations are being reflected in the market as well. Capral's current stock price is AUD 9.17 (as of May 13, 2025), signalling strong investor confidence. The consistent focus on sustainable innovation and large-scale collaborations is a key driver behind this positive momentum.

The partnership between Stormtech and Capral highlights how thoughtful material selection can align innovation with environmental goals. With the new Wave Grate, both companies are setting a precedent for sustainable product development in the built environment.

Responses