The Center for Automotive Research’s (CAR) Coalition for Automotive Lightweighting Materials (CALM) announced a new study on Wednesday that tested mass reduction in a 2011 Honda Accord roof. The study showed OEMs could achieve 39% vehicle weight reduction, compared to steel and composite counterparts by converting to aluminium or carbon fiber. It showed OEMs would achieve 10 per cent overall mass savings by converting a steel roof to aluminium or carbon fiber. However, aluminium packed more favourable performance and stiffness in the vehicle overall.

CALM is a collaboration of more than thirty industry leading organizations working to support weight reduction in vehicle with effective use of mixed materials in a cost-effective way. CAR research engineer and study co-author Shashank Modi cited CALM for being a rare organization dedicated to mixed-material automotive design. The CALM study’s findings also highlighted the growth of aluminium in replacing steel for mass savings in vehicle roof panels and closures. The study presented three lightweight roof designs as case studies.

{alcircleadd}The study showed substituting a roof panel can considerably cut weight in a vehicle. It showed how a 2011 Honda Accord roof achieved 22-40 per cent weight reduction by switching parts to materials like higher-strength steels, composites and aluminium. If an OEM is required to cut 15 per cent of vehicle weight, nearly every roof panel becomes aluminium or carbon-fiber. The CALM study hopes to examine an all-aluminium version of the roof in future.

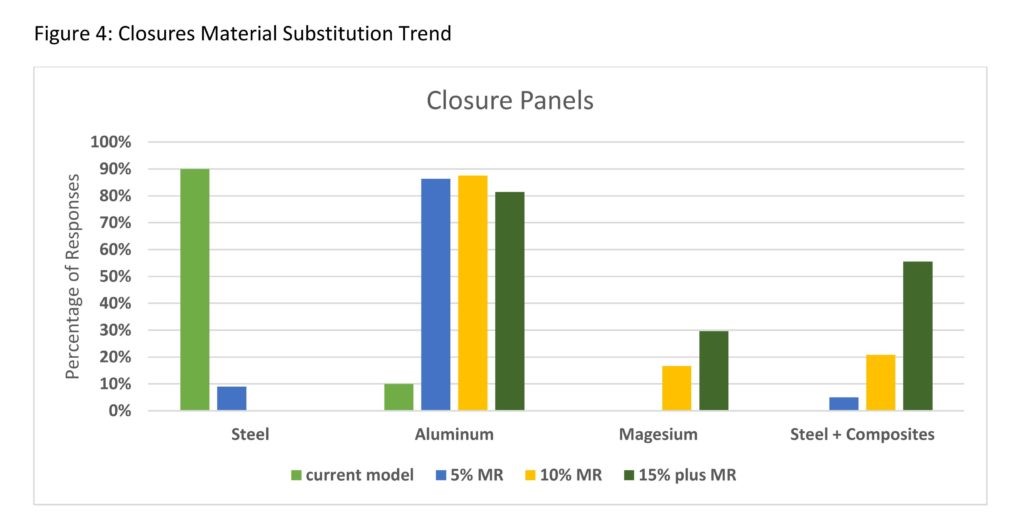

“To achieve (lightweighting) automakers are most likely to use aluminium for up to 15% curb weight reduction and polymer composites beyond 15% curb weight reduction,” CALM said. Based on CAR’s data using aluminium in closures achieves 5 per cent weight cut.

“The data shows that, while 90% of the current closures are made from steel, with as little as a 5% objective to lightweight a vehicle will result in an 85% transition from steel to aluminium,” CAR added.

The study said Body-in-whites applications use a variety of mix-material techniques to cut mass at a range of 5-15 per cent. Modi gave the example of Ford switching the F-150 to aluminium successfully, which was 732 pounds lighter than the 2014 steel F-150. CAR concluded that a typical 2015 model-year vehicle was “an advanced high strength steel body-in-white with mixed steel & aluminium closures.”

Responses