Brembo’s journey toward a 100 per cent recycled aluminium caliper began with a bold ambition: to merge sustainability with uncompromising braking performance. The Italian manufacturer undertook an intensive development process, reengineering its casting, machining and validation systems to accommodate the new alloy without altering the mechanical integrity or aesthetic identity of its products.

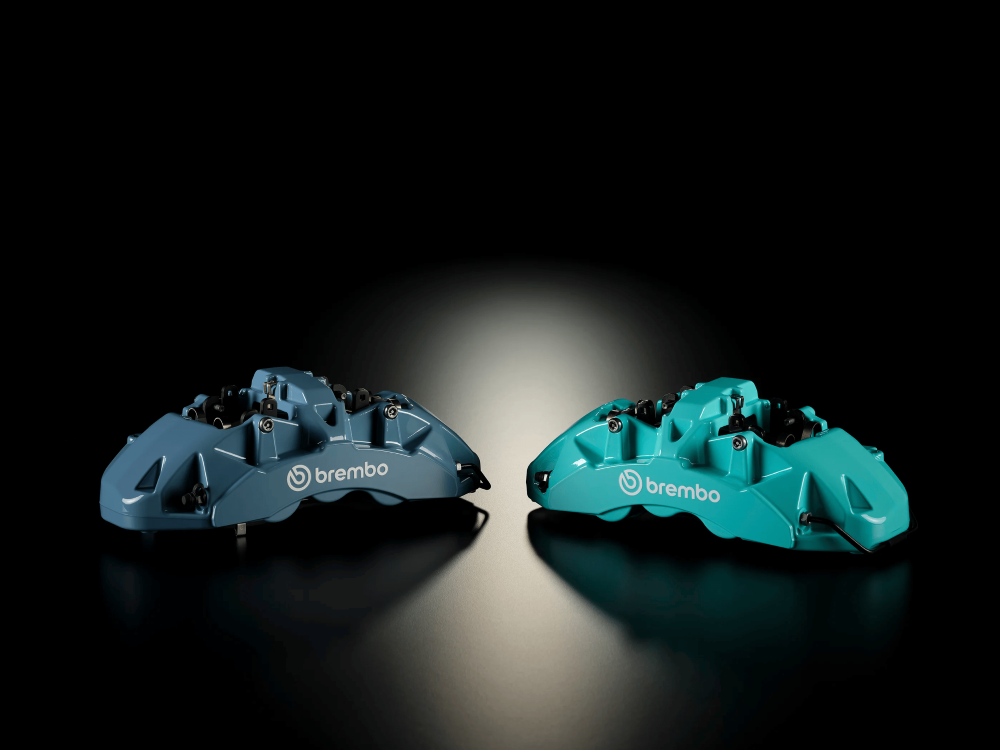

Image credit: brembo

The company reports that the new aluminium formulation reduces life-cycle CO₂ emissions by up to 70 per cent compared to conventional alloys. Achieving this required revisiting each production stage, from raw material sourcing to heat treatment, to ensure consistent strength and precision. Brembo also implemented advanced traceability protocols and created uniform standards across its global network.

To enable large-scale adoption, Brembo aligned suppliers and retooled plants in Europe, the US, Brazil, Mexico, China, India, Japan and Thailand. The recycled alloy was developed to be locally available in every production region, minimising logistics and carbon impact. Calipers manufactured under this initiative will bear a distinct “ALU” logo to signify their recycled composition.

Also read: Alupro-SUEZ collaborations aim to enhance aerosol recycling in the UK

Transitioning to this new aluminium specification has involved careful cost management, as price parity will determine broader OEM acceptance. Brembo has already begun supplying one of its key customers, suggesting that production motorcycles featuring the new alloy may already be on the road. For ongoing models, the company will continue using conventional aluminium until the end of their product life, while prioritising renewable-energy aluminium for future designs.

To know more about the recycled aluminium market, read “World Recycled ALuminium Market Analysis Industry forecast to 2032”

Responses