With an agreement that expects to reconfigure India’s rare earth supply chain, India’s BatX Energies and Germany’s Rocklink GmbH recently signed a groundbreaking Memorandum of Understanding (MoU) to design the first fully integrated rare earth magnet recycling and refining ecosystem in India. Announced on July 18, 2025, the cooperative agreement highlights the more comprehensive objectives of enhancing Indo-European cooperation in critical minerals as part of the EU–India Trade and Technology Council (TTC).

Image source: Fortune

Image source: Fortune

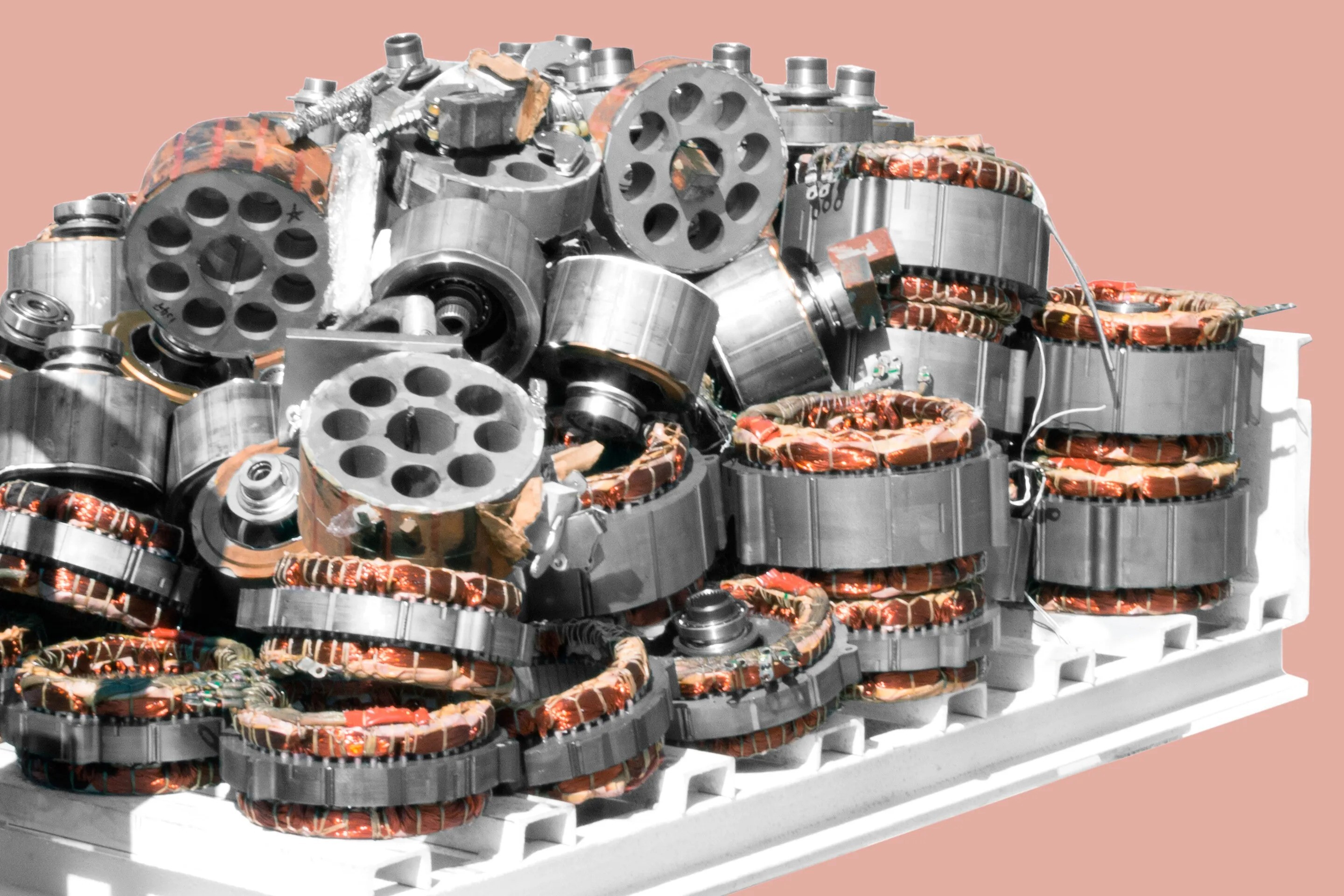

The project aims to tackle an urgent chokepoint in manufacturing clean tech around the world: rare earth elements (REE). The REEs include neodymium, praseodymium, dysprosium and terbium. All of these are key materials in electric vehicle motors, generators for wind turbines, and consumer electronics; yet their supply chains remain heavily dominated by China.

More about the strategic collaboration for circular REE supply chains

BatX Energies, a lithium-ion battery recycler, and the German company Rocklink GmbH, a leader in the recovery of rare earths, are embarking on a joint project to deploy Rocklink's patented Magcycle™ reverse logistics platform to collect end-of-life NdFeB, SmCo and AlNiCo magnets from discarded motors and industrial equipment throughout India.

This is one of the few noteworthy lithium-ion recycling ventures started last year by Hydrovolt, RecyLiCo, Attero and Mahindra Last Mile Mobility, Altilium, TES and so on.

The project will also establish a zero-liquid-discharge (ZLD) rare earth refining plant that adheres to international export standards. New advanced solvent extraction (SX) technology will also be developed jointly to provide a solution for the isolation of high-purity rare earth elements (REEs), a key component of a circular economy model, with the potential for India to deliver on its clean energy agenda.

Utkarsh Singh, CEO of BatX Energies, emphasised the strategic importance of the partnership:

“This partnership marks a defining moment in India’s journey toward rare earth self-reliance.” He also added, “We’re proud to lead this initiative alongside Rocklink and to advance the EU TTC vision for circular and transparent mineral supply chains.”

Leonard Ansorge, Director at Rocklink GmbH, said, “Our collaboration with BatX combines our refining expertise with their innovative on-ground execution to deliver results in short development cycles.”

From pilot to commercial scale

A pilot facility is expected to be operational in 12 months, with a target for commercial-scale production within two years. They have previously established India’s first lithium-ion battery and magnet recycling cluster in Sikandrabad, Uttar Pradesh, giving them a working hub to scale the operations.

Notably, this action also aligns with EU efforts to promote rare earth diversification and reduce supply dependency. Under the TTC mechanism, both parties will conduct co-development and patenting technologies in India and Europe, resulting in a joint IP portfolio potentially generating long-term strategic value.

This announcement could be a turning point for India, both economically and geopolitically, by providing a foothold in the non-Chinese rare earth ecosystem.

Note: To feature your brand and share insights, contribute an article or interview in our forthcoming e-magazine "Sustainability & Recycling: Aluminium's Dual Commitment."

Responses