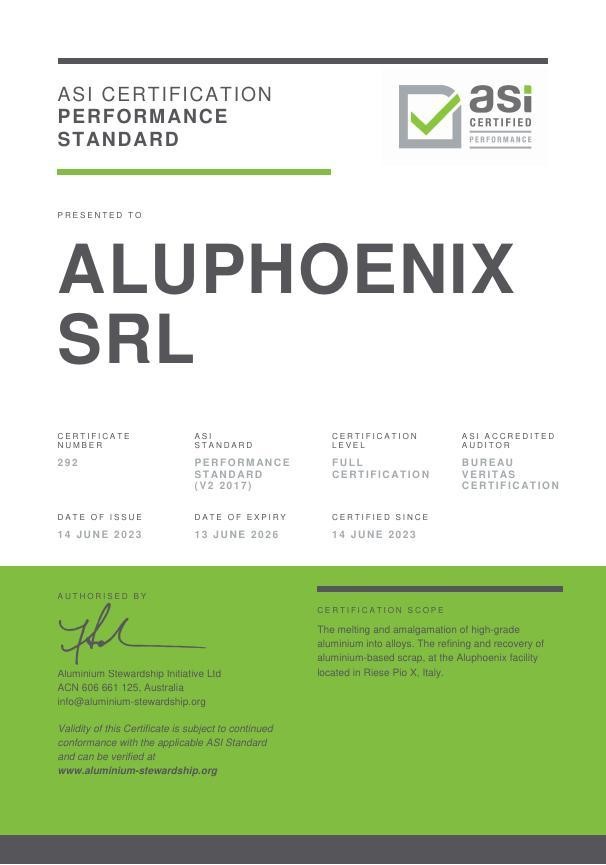

Aluminium Stewardship Initiative has presented Performance Standard V2 (2017) Certification to Aluphoenix srl for its remelting and casting facility in Riese Pio X, Italy. The facility has an annual production capacity of around 50,000 tonnes of aluminium ingots destined for transportation.

Aluphoenix is specialised in melting and amalgamation of high-grade aluminium, such as from pre-consumer and post-consumer scrap into alloys in the form of ingots. These products are used for air and marine transport, renewable energy, and automotive sectors. Last year, the company produced aluminium alloys from 11,291 tonnes of recycled materials.

The ASI Performance Standard V2 (2017) defines environmental, social, and governance principles and criteria, aiming to address sustainability issues in the aluminium value chain.

The independent, third-party audit of Aluphoenix’s ASI-certified facility was conducted by Bureau Veritas Certification.

On receiving the certification, Lino Parise, CEO and Chairman of Aluphoenix, said: “‘At Aluphoenix, we understand the critical role we play in promoting sustainability throughout the aluminium value chain. As a producer of primary, special, structural and hyperpure aluminium alloy for foundry, we focus on implementing sustainability practices on the ground that minimise our environmental impact, contribute to a more circular economy. Further, they enhance the lives of our workers and community, while exemplifying the ethical principles that drive our entrepreneurial vision. This ASI certification validates our efforts to towards responsible sourcing of raw materials and production of aluminium alloy, including maintaining a fertile working environment for our employees. By adhering to this rigorous standard, we are proud to support our customers’ sustainability goals and more broadly, contribute to the overall sustainability of the industry.”

Fiona Solomon, Chief Executive Officer at ASI, commented: “We sincerely congratulate Aluphoenix for achieving Performance Standard Certification for their remelting and casting operation in Riese Pio X, Italy. The company leverages its many years of experience and innovative spirit to ensure high-quality products for its customers. Aluphoenix’s ASI Certification demonstrates that the company is also committed to address environmental, social, and governance (ESG) aspects of its production process.”

Responses