您想继续阅读英文文章还

是切换到中文?

是切换到中文?

THINK ALUMINIUM THINK AL CIRCLE

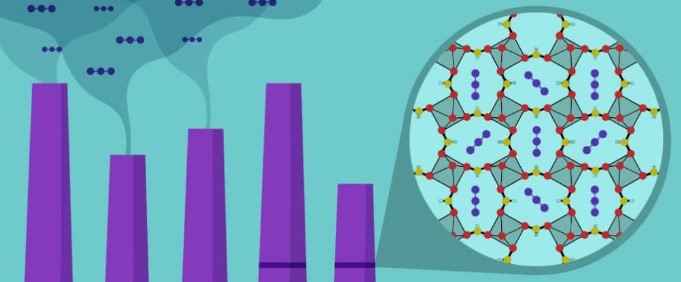

Coal-fired power stations are responsible for 30 per cent of the world's CO2 emissions. Even while the globe is embracing alternative energy sources that don't produce greenhouse emissions, including solar and wind power, finding a technique to lower the carbon output of existing plants might help minimise their effects while they are still in operation.

According to reports, researchers from the National Institute of Standards and Technology (NIST) developed a metal-organic framework (MOF) called Aluminium formate (ALF), which can distinguish carbon dioxide (CO2) from other chemicals that escape the smokestacks of coal-fired power plants. It also doesn't have the drawbacks that other suggested carbon filter materials do.

"What makes this work exciting is that ALF performs really well relative to other high-performing CO2 adsorbents, but it rivals designer compounds in its simplicity, overall stability and ease of preparation. It is made of two substances found easily and abundantly, so creating enough ALF to use widely should be possible at very low cost," said Hayden Evans, a chemist at the NIST Center for Neutron Research (NCNR).

Evans claims that removing CO2 from flue gas before it is released into the environment makes sense, but developing an efficient scrubber has proven difficult. Finding a cost-effective material that can do the task effectively has been challenging because of the gas combination's hot, humid, and corrosive nature that commonly flows up the smokestacks of coal-fired power plants.

ALF is a minuscule version of a three-dimensional wire cage with many tiny openings. These gaps are precisely sized to reject the slightly bigger nitrogen molecules that make up the bulk of flue gas while allowing CO2 molecules to enter and become trapped. The researchers could see through neutron diffraction studies how the individual cages in the material gathered and filled with CO2, demonstrating how the gas molecules fit snugly inside some of the ALF cages.

ALF has potential, but it has yet to be ready for usage. A process would need to be developed by engineers to produce ALF on a big scale. Before cleaning the flue gas, a coal-fired plant would require a corresponding procedure to lower its humidity. Evans said that many solutions to these problems are already well known and would not significantly increase the price of adopting ALF.

While certain MOFs are less expensive in and of themselves, they operate effectively under dry circumstances only, necessitating a "drying phase" that lowers the gas humidity but increases the total cost of the scrubbing process. Other MOFs are comprised of high-quality materials but are expensive to produce.

Responses