The DC casting method, a well-known casting technology for 50 years, involves feeding molten aluminium into a mould. This molten metal is subsequently subjected to cooling through the application of water strategically directed towards the inner wall of a graphite ring. Over time, the DC technology has undergone enhancements, incorporating an oil and gas/air system featuring a porous graphite mechanism for the initial cooling zone, while water serves as the secondary cooling medium.

For DC casting, the primary objective is the meticulous creation of an exceptionally thin shell or segregation zone on the billet's surface. The overarching goal is to achieve this without inducing cracks and to produce a structurally uniform grain structure. This process underscores the pursuit of an optimal balance between cooling strategies, aiming to mitigate potential defects and ensure the formation of a homogeneous grain structure.

{alcircleadd}At TRI Metalurji, our scope extends beyond alloy formulation and calculations; we are actively involved in the intricate design of both alloys and moulds/graphite structures. The primary aim is to enhance thermal conductivity within the mould during the solidification process. Notably, our latest mould design is specifically tailored for applications involving 7XXX series aluminium alloys.

The distinctive characteristic of the 7XXX series lies in its significantly broader solidification window compared to the 6XXX series aluminium alloys. While the DC method offers elevated cooling rates, it is crucial to acknowledge that these high rates can induce thermal stresses, consequently elevating the risk of cracking. Consequently, meticulous consideration of casting parameters and mould design assumes paramount importance in ensuring a high-quality surface that is devoid of cracks. To address this challenge, we employ thermodynamic calculations and simulation programs. These tools are instrumental in defining optimal casting parameters, thereby contributing to the attainment of superior surface quality.

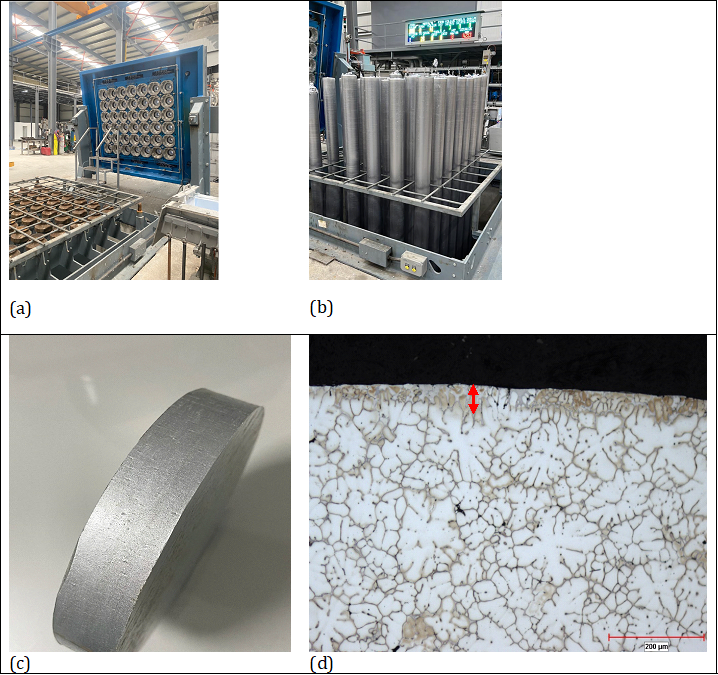

Figure 1 shows an example from high Zinc content (over 6%) 7XXX series trials pictures taken from the casting table, 7XXX billet and microstructure with a very thin segregation zone on the surface.

Figure 1. 7XXX series casting, (a) casting table, (b) billets on the casting pit, (c) slice of the billet and (d) Shell zone of the billet.

While solidification itself is a relatively short-timing process, it poses significant challenges for casthouse engineers. Notably, alloys with a wide solidification window, such as the 7XXX and 2XXX series, introduce complexities when encountering reduced cooling rates in the first cooling region or diminished water flow in the second cooling region. This scenario presents two distinct risks: the potential for premature solidification within the mold and the risk of bleeding out during the casting process.

TRI Metalurji distinguishes itself by adopting a comprehensive approach that incorporates various metallurgical techniques. Our commitment to quality spans the entire spectrum, commencing from meticulous laboratory-scale experiments and extending to mid-scale operations, as illustrated in Figure 1. This integrated strategy enables us to navigate the intricacies of the solidification process, addressing challenges associated with diverse alloy properties and ensuring the delivery of superior-quality products.

Responses