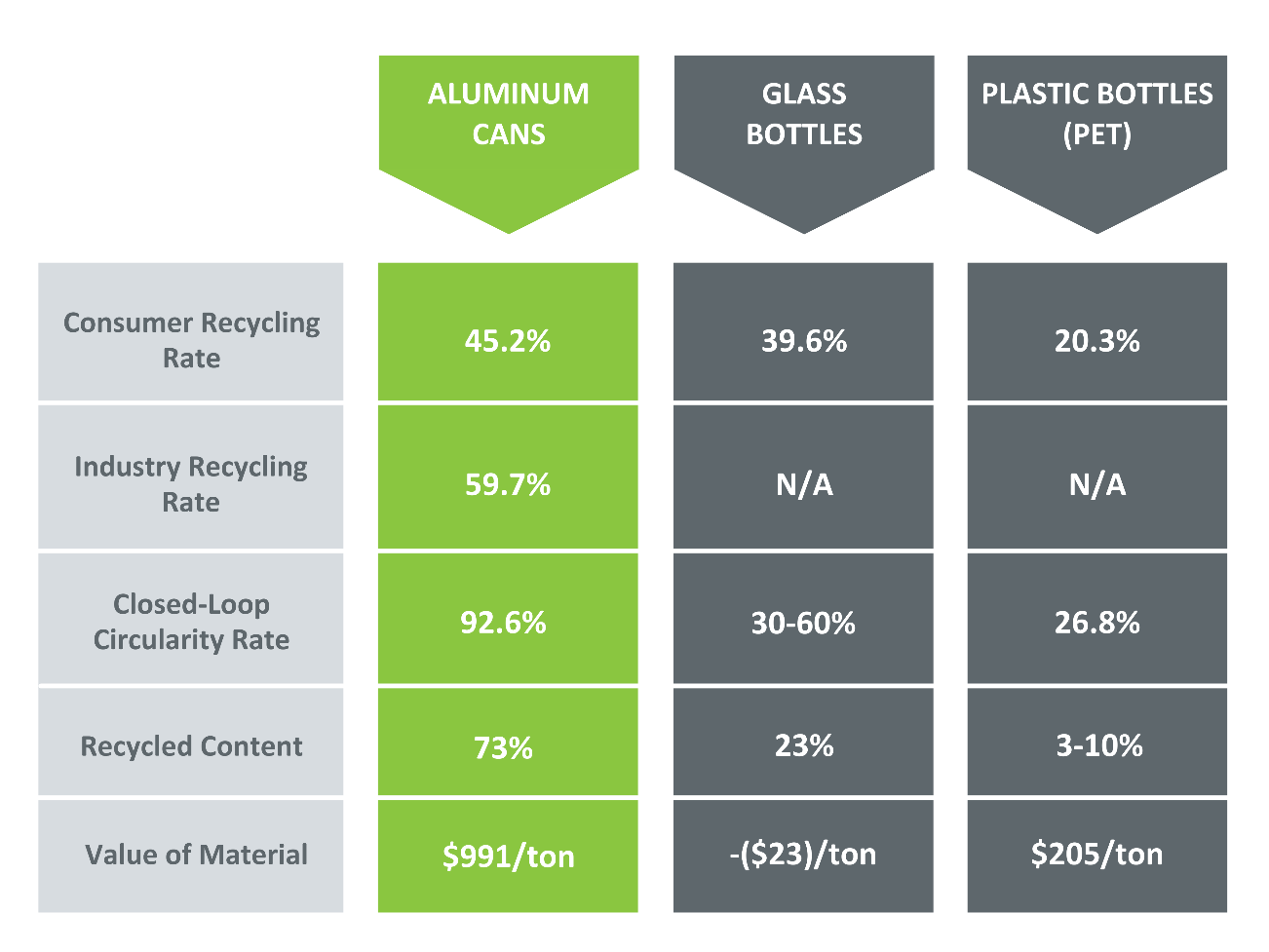

The Aluminium Association and the Can Manufacturers Institute (CMI) have produced an updated analysis highlighting the aluminium beverage container's continuous environmental benefits over competitor packaging materials. As per the study, consumers recycle aluminium cans at more than twice the rate of plastic (PET) bottles, which updates many key performance indicators (KPI) for 2020. Aluminium beverage cans also contain 3X to 20X more recycled content and are significantly more valuable as scrap than glass or PET bottles, making aluminium a primary driver of the financial sustainability of the US recycling system. The closed-loop circularity rate, which evaluates the proportion of recycled material used to go back into the same product – in this example, a new beverage container – is a brand-new KPI in this year's report.

According to the report last year, the rate of consumer recycling of aluminium beverage cans fell somewhat. Despite the COVID-19 pandemic and other market disruptions, the rate fell from 46.10% in 2019 to 45.20% in 2020. Despite the slowing rate, the number of used beverage cans (UBC) recycled by the industry grew by nearly 4 billion cans in 2020, to 46.7 billion cans. Even though can sales increased last year, the rate fell. The average consumer recycling rate over the last 20 years has been approximately 50%.

“Aluminum cans remain the most recycled and recyclable beverage container on the market today. But the U.S. recycling rate for cans lags behind the rest of the world – a needless drag on the environment and the economy. These new U.S. recycling rate targets will catalyze action within and outside the industry to bring more cans back into the recycling stream,” said Raphael Thevenin, Vice President of Sales and Marketing at Constellium and chair of the Aluminium Associations Can Sheet Producers Committee.

“CMI is proud that the aluminium beverage can continue to outperform its competitors on key sustainability metrics. CMI beverage can manufacturer and aluminium can sheet supplier members are committed to building on the beverage can’s superior sustainability performance and have demonstrated that commitment with the industry’s new recycling rate targets. Achieving these targets are not only important to the industry’s growth but also will benefit the environment and the economy,” said Robert Budway, President of CMI.

The closed-loop circularity rate, a new KPI introduced this year, assesses the proportion of recycled material utilised to make a new beverage container. It is partially a metric for determining the quality of recycled materials. When items are recycled, the recovered resources might be utilised to manufacture the same product or a lower-grade product (closed-loop recycling) (open-loop recycling). Closed-loop recycling is preferable because the recovered product is often of comparable quality to the parent material, and the process may be repeated several times. Open-loop recycling, on the other hand, might result in material quality degradation due to a change in chemistry or an increase in contamination in the new product.

The following are some of the report's other main conclusions for 2021:

The increased aluminium beverage can recycling rates will have a significant influence on the domestic aluminium industry's overall sustainability. The organisation issued a new third-party life cycle assessment (LCA) analysis earlier this year that showed that the carbon footprint of aluminium cans manufactured in North America has decreased by nearly half over the last three decades. Recycling a single can also save 1.56 megajoules (MJ) of energy or 98.7 grammes of CO2 equivalent, according to the LCA. This implies that recycling a 12-pack of aluminium cans saves enough energy to run a standard passenger automobile for approximately three kilometres. Recycling the aluminium beverage cans that now end up in landfills in the United States could save the economy $800 million and enough energy to power more than 2 million households for a year.

Responses