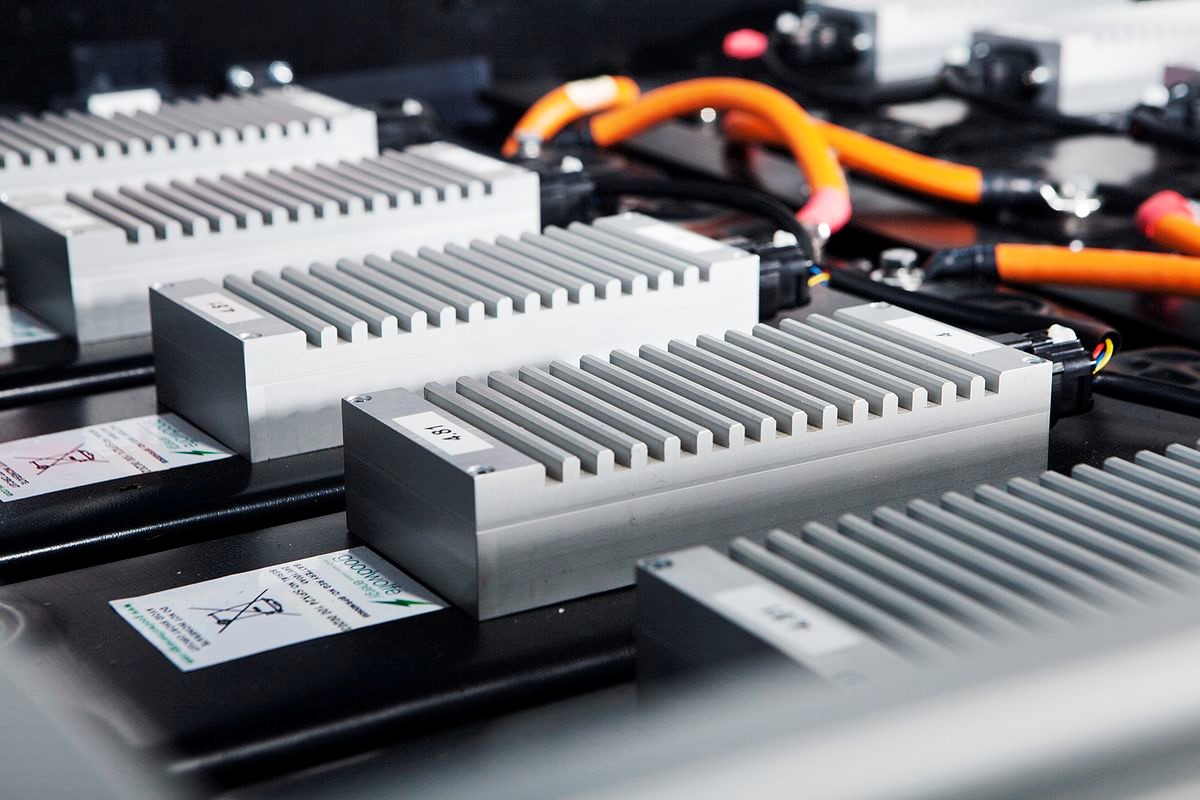

According to a recent finalized study completed by AluMag, 43% of all New Energy Vehicles (NEVs) produced in China are fitted with an aluminium tray, which forms the lower part of the EV battery housing. Out of that, 36% has extruded aluminium while 7% has a cast aluminium tray. The remaining 57% are fitted with steel trays.

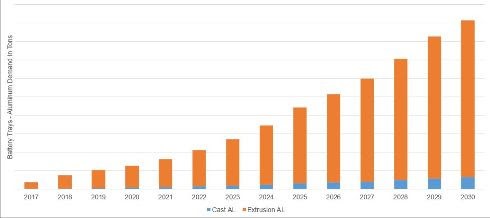

AluMag forecasts that the NEV penetration in China would grow from 2.5% in 2017 to 32% in 2030. The study calculates if China delivers an estimated 10 million NEVs by 2030, aluminium extrusion & cast demand would grow with a CAGR of 28% between 2017 & 2030.

{newsStudioGallery}

Use of aluminium is growing mostly in the A segment cars. However, about 50% of the Chinese NEV market currently consists of A & B segment cars where aluminium is scarcely used in the battery tray. The bulk demand for aluminium battery trays mostly come from C & D segment NEVs. The production of E-Segment cars in China is very low in terms of volume and foreign OEMs only account for about 2% of NEVs being produced in China.

Suppliers of cast and extruded aluminium are betting big on battery trays. But alternative material & battery technologies may influence the demand for aluminium within this segment. Several OEMs are planning to introduce EVs with solid state batteries around 2025 to 2030 at the latest with a significant stake because of longer range and shorter charging times. These are the two of the biggest hurdles for EVs to reach mass markets.

This will drive higher penetration for NEVs but not necessarily boost demand for extruded and cast aluminium battery trays. Solid state batteries does not require cooling/heating like lithium batteries and are less likely to catch fire. Solid state battery housings are therefore likely to utilize other design / materials / processes.

Advanced High Strength Sheet Steel (AHSS) can also pose further threats to aluminium as an alternative material for battery trays.

AluMag Automotive analysed 81 of the world`s most popular NEVs., 44 Chinese models as well as 37 foreign models from Europe, USA, Japan & Korea while concluding this study. In terms of the aluminium penetration, 55% of the Chinese models featured an aluminium battery tray and 58% of the foreign models.

Responses