您想继续阅读英文文章还

是切换到中文?

是切换到中文?

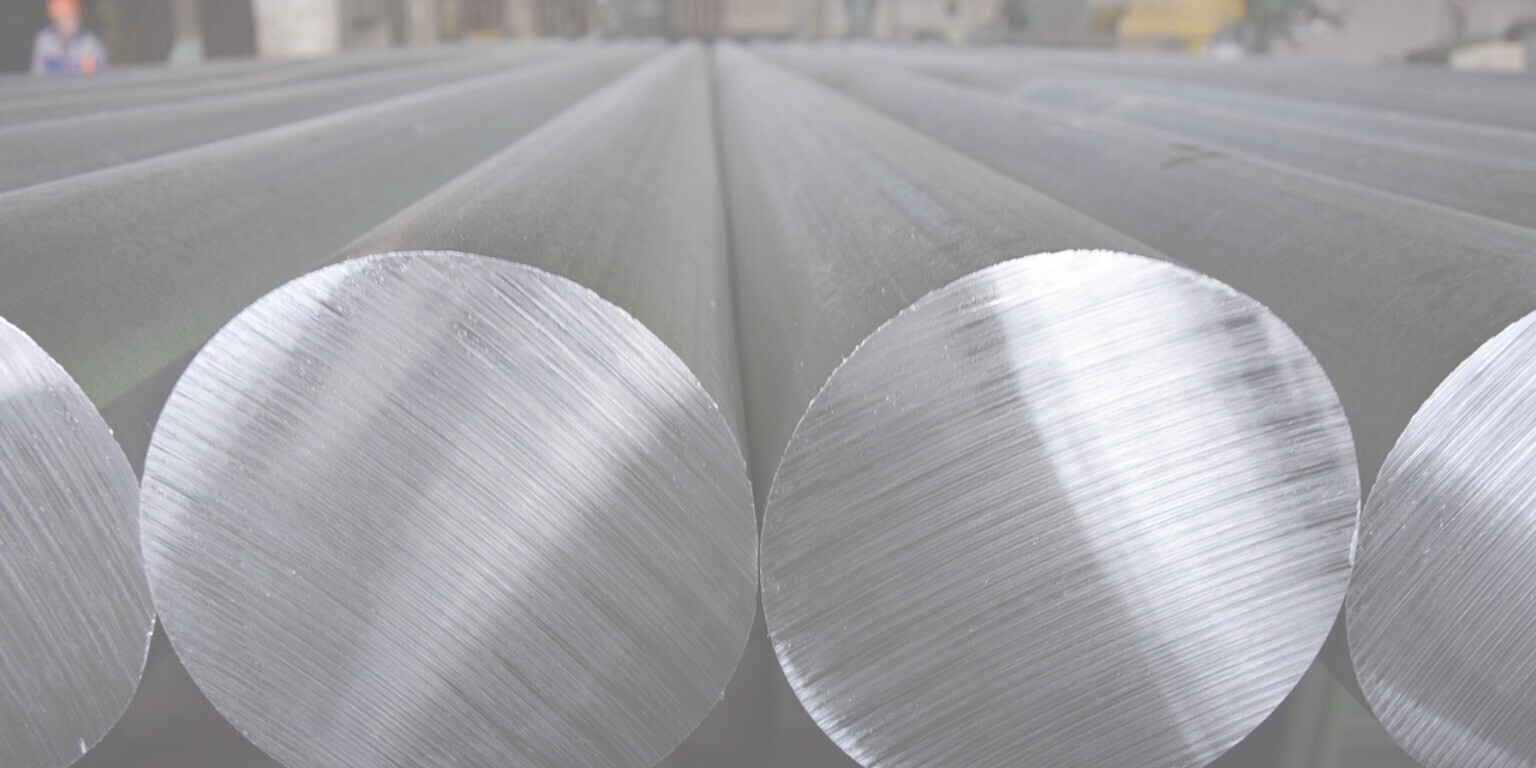

THINK ALUMINIUM THINK AL CIRCLE

The biggest announcement in the Industrial Strategy, the British Industry Supercharger expanded to give up to 90 per cent relief on electricity network charges, up from the previous 60 per cent,a significant milestone for over 7,000 energy-intensive businesses. For the aluminium processors and producers alone, energy is a high proportion of their operating costs. “Energy competitiveness is a defining issue for the aluminium sector. Without decisive support, producers and processors across the UK risk becoming globally unviable,” noted Nadine Bloxsome, CEO of ALFED.

However, as Bloxsome also cautioned, “The Supercharger expansion is a major step forward, but we now need urgent clarity on who qualifies, how SMEs can benefit, and how this aligns with future emissions reporting obligations.”

In spite of these strategies, aluminium, one of the most recyclable, lightweight and low-carbon metals, did not make the Industrial Strategy mention. The notation is symbolic not just in that, but in a wider policy gap.

The policy only says "metal" once. This is in total contrast to the critical role aluminium plays in clean energy infrastructure, electric vehicles, sustainable construction, aerospace, and defence, all of which are priority areas in the strategy. ALFED indicated that neglect of materials like aluminium could be damaging to its wider sustainability targets.

Moreover, Bloxsome further stated that “The Industrial Strategy gives us a foundation. Now we must fill in the gaps. Through the UK Aluminium Alliance, we are mapping our national capacity, building technical partnerships with OEMs, and pushing for aluminium’s full recognition as a strategic material, on par with steel, defence metals and advanced composites.”

The strategic edge of aluminium - why recognition matters

ALFED stated previously that this Industrial Strategy is a positive start, but it will take commitment from everyone and collaboration from Government for it to be a success. ALFED highlighted the EU's Carbon Border Adjustment Mechanism (CBAM) and calls on the UK to align around policies that are consistent with real world emissions, especially Scope 2 emissions related to electricity consumption in manufacturing.

Moreover, skills development is an ongoing concern. Their members still express their need for skilled labour. Apprenticeship programmes based around green manufacturing and the circular economy may support closing the gap.

From policy mention to material priority

The aluminium sector is not simply demanding handouts. It is requesting a seat at the table. Launching the UK Aluminium Alliance, it aims to formalise that seat through the collation of data, coordination of national capabilities and delivery of targeted advocacy across government departments.

The shift by ALFED to move from reactive policy feedback, to proactive alliance building may change the conversation around aluminium in Britain's industrial future.

Responses