As the year's first half almost winds up, AL Circle feels excited to announce the launch of its latest panoramic report, Digital Transformation in the Aluminium Industry, which cites the major digital upgrades in the aluminium value chain and justifies its usage. The report features a comprehensive study on data analytics, automation, IoT (Internet of Things), AI, Industry 4.0, blockchain and deep learning.

The aluminium industry uses extensive energy and has a vast operational base, with multiple actions happening simultaneously to achieve a particular state. From bauxite mining to alumina refining and from primary aluminium production to downstream and end-user processes, it is imperative to track every activity for minimum material loss and quality inspection.

Currently, the aluminium industry is undergoing a digital transformation that integrates digital technologies and data-driven strategies to improve production, processing, and distribution. This comprehensive approach aims to boost efficiency, cut costs, and enhance competitiveness within the industry. The transformation involves a diverse range of technologies and practices that are geared towards achieving these objectives.

These technologies include data analytics and machine learning for predictive maintenance, automation and robotics for improved precision and productivity, IoT devices for real-time monitoring and control, and supply chain optimisation for efficient logistics. Additionally, energy efficiency is achieved through the use of digital technologies to monitor and optimise energy consumption, while quality control is enhanced through advanced sensors and AI.

COVID-19 and the Russian-Ukraine conflict have been peripheral to the concept of introducing digitalisation in heavy industries. The worldwide lockdown has taught our civilisation how important it is to increase digital tracking and virtual vigilance because it is not always possible for a man to perform uniformly at every moment of his life. Moreover, global occurrences like the pandemic might dilute the ability of man.

Customer engagement is improved through digital platforms that offer real-time order tracking, customisation, and digital catalogues. Block chain technology is used for traceability, and 3D printing technology is adopted to create precisely engineered bespoke components with reduced material waste. Lastly, robust cybersecurity measures are implemented to protect sensitive data and prevent cyber threats.

In summary, digital transformation in the aluminium industry is a holistic approach that benefits the industry, sustainability, and innovation in aluminium production. Leading software providers like Microsoft, IBM and Amazon web services have voted to uplift the aluminium industry with their technological prowess and automation skills. This will help simplify the production processes, scrutinising and levelling the data at every moment to obviate any unprecedented event or sudden life-threatening incidents.

At a glance, the report ‘Digital Transformation in the Aluminium Industry’ covers the following topics:

To have a look at the detailed Table of Contents, click here.

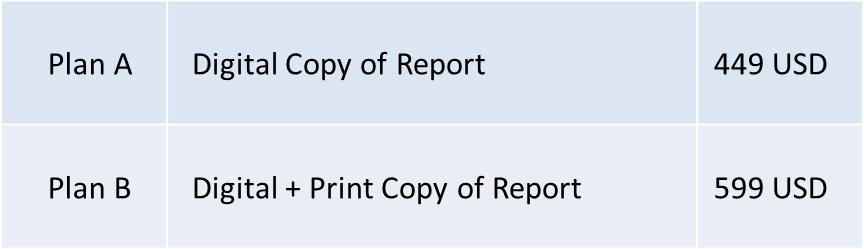

The Digital Transformation report is now available in both print and digital medium. In the table below, you’ll find the pricing of each:

Your wait is over, as you can buy the report by emailing us at booking@alcircle.com, or you can directly click the link to buy the report.

Responses