Oerlikon AM and Airbus have prominently commercialised the 3D printing technology for producing precisely engineered antenna clusters that will be used in communication satellites orbiting Earth. This denotes a significant achievement in their ten-year alliance, resulting in a €3.8 million deal to additively manufacture these satellite components, mainly with 100% recyclable aluminium.

The R&D Manager for Additive Manufacturing of RF Space Components, Airbus, Michael Kilian, commented: “To create a final product of excellent quality, technical cooperation and understanding each other’s needs and requirements is fundamental for a well-coordinated design and manufacturing process – not only in rapid prototyping but even more so in serial production.”

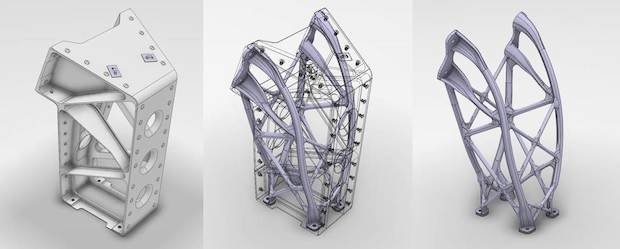

Both companies have been collaborating for over a decade, developing additively manufactured metal parts for space. The aluminium antenna clusters, measuring approximately 400x400x400 mm, are manufactured applying laser powder bed fusion technology and are part of the next-generation communication satellites that will receive and transmit communication or data signals in K-band frequency.

The Managing Director of Oerlikon AM, Hendrik Alfter, notified: “The key success factor is the specific AM machine setup, which allows the family of geometries to be reproduced with the required accuracy and the process to be indefinitely repeated. Thus, we met the high accuracy and quality requirements of Airbus and, consequently, the specified European Space Agency (ESA) standards for satellites. We are pleased that the cooperation has resulted in a €3.8 million multi-year contract for the supply of antenna clusters.”

Additive manufacturing is crucial in space applications because it can aid in ample weight reduction, which is vital for surpassing unnatural mass, reliability, and sustainability issues. AM has also reduced the production lead time for an antenna cluster from six months to a few weeks compared to a usual manufacturing method.

As an all-around service provider, Oerlikon AM offers printing, post-processing, surface finish optimisation, precision CNC milling, quality assurance, ultrasonic cleaning, assembly, wire integration, and tailored logistics. The two parties have jointly stapled the post-processing as a primary segment of the operational guidebook. Oerlikon AM is a registered and qualified supplier with a great track record with Airbus. Most of all, the company passes all the related audits each year.

Responses