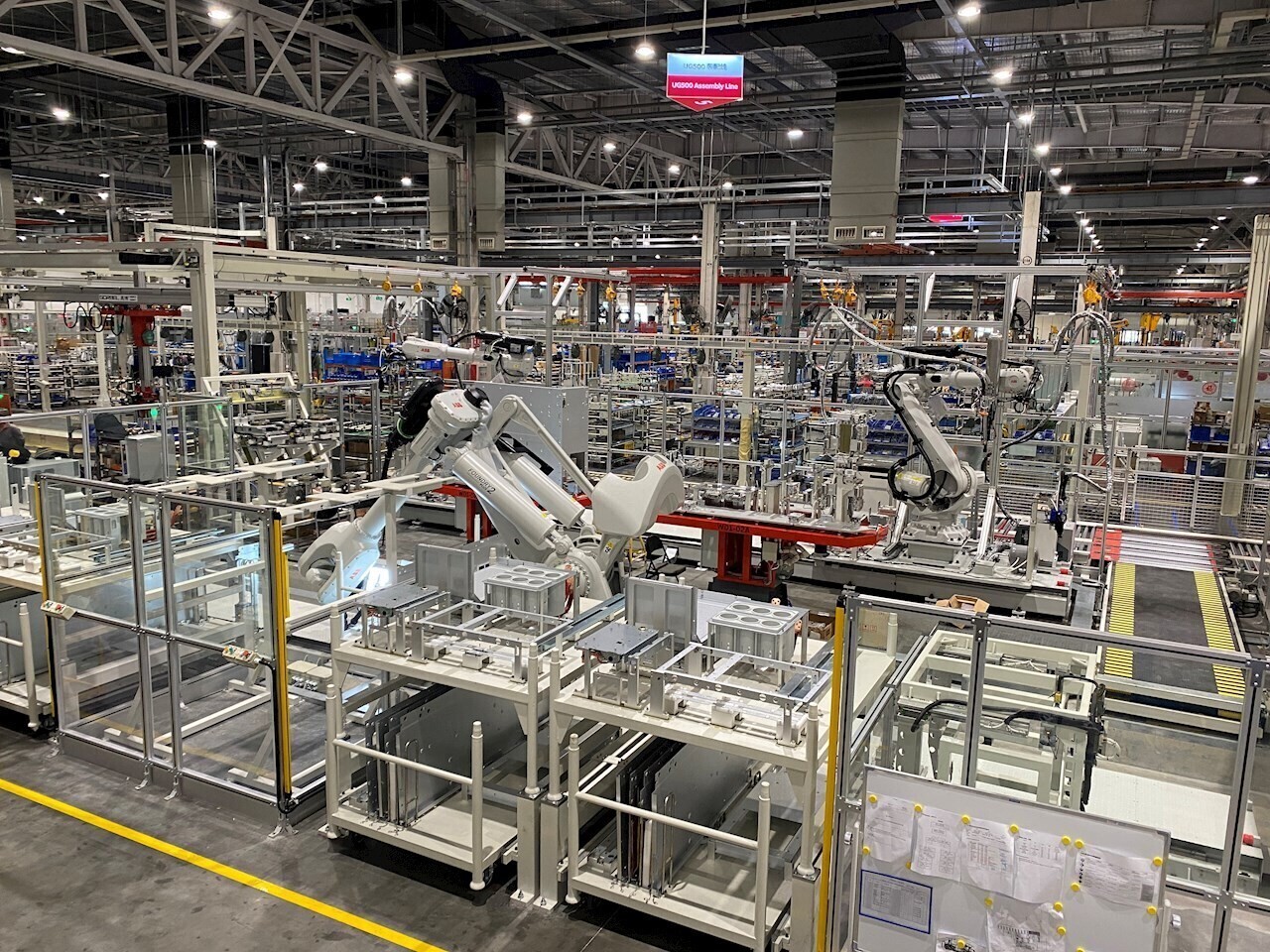

In a landmark move towards sustainable manufacturing, ABB's key production facility in Xiamen, China, emerged as a decarbonisation paragon. This site, which is renowned for producing low—and medium-voltage switchgear and circuit breakers on state-of-the-art production lines, has significantly reduced its annual CO2 equivalent (CO2e) emissions.

Leveraging advanced smart digital technology, the Xiamen facility has slashed its CO2e emissions by an estimated 13,400 tonnes, benchmarked against a 2022 baseline. This achievement is a testament to ABB's global Mission to Zero program, which aims to drive down carbon emissions across its operations worldwide.

The Xiamen site's success highlights the potential for integrating smart technology to enhance sustainability in industrial manufacturing. ABB's efforts in Xiamen underscore the company's commitment to environmental stewardship and provide a model for other manufacturing sites striving to reduce their carbon footprint.

The site integrates multiple technologies and solutions to achieve decarbonisation, featuring 100,000m² of rooftop solar panels that generate approximately 50 per cent of the site's annual electricity consumption. A smart energy management system anticipates electricity generation by analysing weather conditions and forecasting the future power production of photovoltaic (PV) panels. ABB's ZEE600 control system oversees the site's complex energy ecosystem, monitoring and managing loads, battery storage, and EV charging to optimise energy usage across the 425,000m² facility, which employs over 3,000 people. Modular power solutions facilitate the connection of various PV fields, batteries, factory loads, and EV chargers.

Installing new technologies has transformed ABB Xiamen into a flagship site for sustainable manufacturing, providing a blueprint for a clean energy future in China with significant emission and cost reductions. At the heart of ABB’s Sustainability Agenda is the commitment to reducing emissions within its operations to foster a more sustainable and resource-efficient future. The solutions implemented at ABB Xiamen are designed with modularity, making them easily replicable.

James Zhao, the Senior Vice President of ABB China, said, “The scale and pace of our Xiamen carbon reduction journey is our most powerful example of how manufacturers of any size can create low carbon production sites – and quickly. By implementing ABB technology, which is widely available, we are showing how to accelerate the journey to decarbonization. Our world-class demonstration site will show our customers and partners how low carbon ambitions can be achieved today through intelligent technology.”

Like ABB's Mission to Zero sites in Lüdenscheid, Germany, and Santa Palomba, Italy, the ABB Xiamen facility demonstrates to customers and manufacturers how smart digital technology can facilitate their path towards decarbonisation.

Responses