您想继续阅读英文文章还

是切换到中文?

是切换到中文?

THINK ALUMINIUM THINK AL CIRCLE

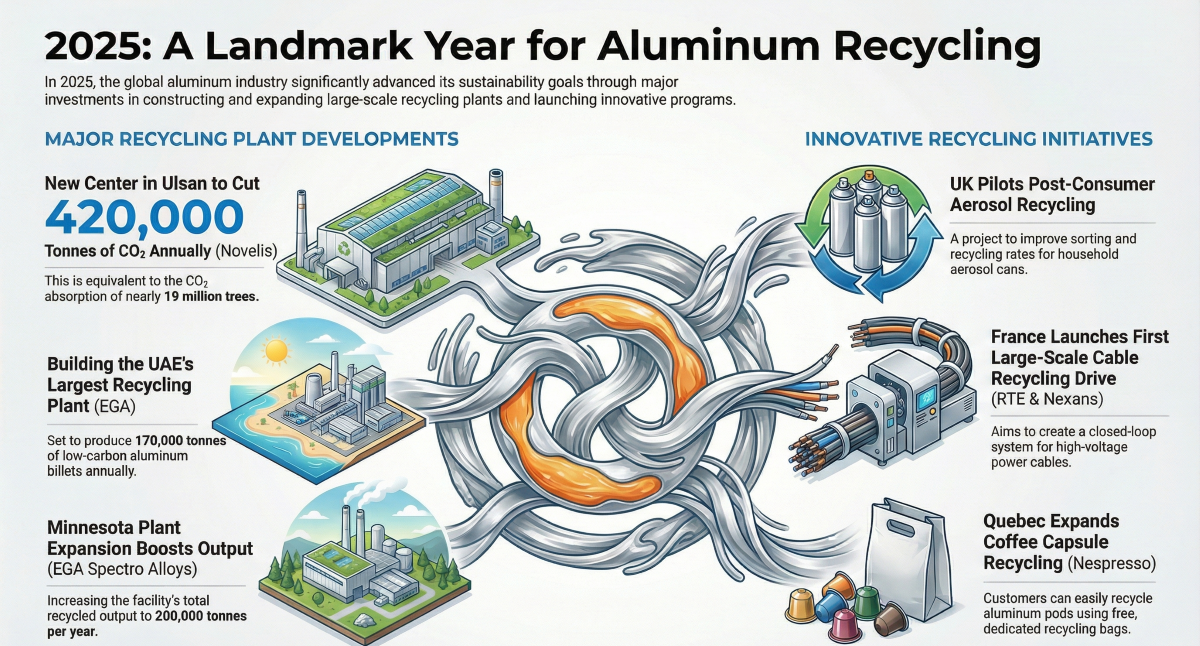

2025 has been the year when major industries, especially the global aluminium industry, have been more proactive towards either starting new aluminium recycling projects or restarting the existing ones. Since the year is about to end, now is the right time to have a look at the key projects concerning the global aluminium recycling and make an informed decision for the year to come.

Highlighting some of 2025’s key recycling projects

The largest recycling plant in the UAE, powered by EGA

…and so much more!

SIGN UP / LOGINResponses