Irrespective of aluminium being hyped for its lightweight yet strong feature, it loses its strength at high temperatures. Keeping this in mind, the researchers at Nagoya University developed a metal 3D printing technique to create a new line of aluminium alloys for increasing the strength and higher heat resistance. These alloys are made by using low-cost and abundant elements, which are 100 per cent recyclable, where one variant is deemed to be strong and flexible even at 300°C.

New methods breaking the traditional stereotypes

The lead author and the professor at the Nagoya University Graduate School of Engineering have explained that the design centres on iron, where the metallurgists do not usually add aluminium, as it tends to make the metal highly vulnerable to corrosion and brittle.

To this, he further added that the rapid cooling rates within the laser power bed fusion, a key process of the metal 3D printing technologies, enable the molten metal to solidify within seconds. This feature of faster cooling alters the fundamental rules as it taps iron and other elements within the arrangements, especially during the formation of metastable phases, which cannot be done within the contemporary manufacturing conditions. With the effective selection of the right elements to add, the creation of the new aluminium alloys with higher heat-resistance and strong features is significantly possible.

Must read: Key industry individuals share their thoughts on the trending topics

Research method leading to success

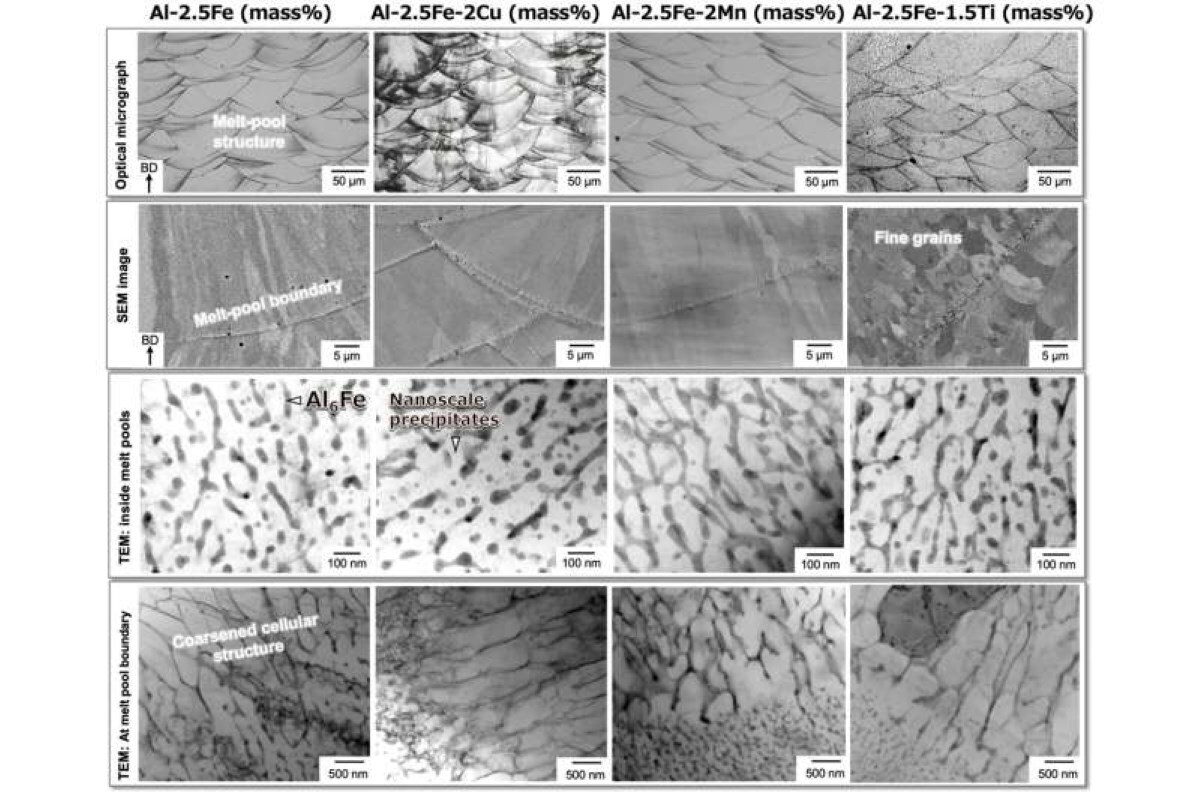

The University researchers have created a systematic method which aids in predicting and selecting the right element that will support in strengthening the aluminium matrix, as well as identify which would create protective micro- or nano-scale structures. These predictions are further tested by the researchers by developing new alloys using copper, titanium and manganese and confirming the outcome via electron microscopy.

The test reflected that the top-performing alloys are usually made with aluminium, iron, manganese and titanium (Al–Fe–Mn–Ti). It has been noted that these alloys are able to outperform the 3D-printed aluminium materials by combining strength at the highest temperatures while still being flexible at room temperature.

Professor Takata further noted that the researcher's methods highly rely on the previously developed scientific principles, which show how elements react at the time of rapid solidification in 3D printing and are applied to other metals. Moreover, these alloys have proved to be easier to 3D print in comparison to the traditionally high-strength aluminium, which are subject to frequent wraps or cracks at the time of fabrication.

Altering the future of vehicles (and aerospace) with fewer emissions

The newly developed materials stand out as it provides the lightweight aluminium components within the parts, which aid in operation at the highest temperatures, especially in the compressor rotors and the turbine components. This way, the weight of the vehicle reduces, reducing the fuel consumption and resulting in lower emission rates.

Apart from vehicles, the aerospace industry is also expected to benefit from this innovation because the engines in the aircraft require materials that are lightweight yet have high resistance to heat. In addition to these applications, this research has further provided a framework exclusive for designing the new classes of metals, which are specifically used for 3D printing and hold the capability to ramp up the development process within various industries.

Explore- Most accurate data to drive business decisions with 50+ reports across the value chain

Responses