György Bánvölgyi, a Senior Process Consultant with extensive experience in research, development, and engineering for the bauxite processing and alumina industry, shared his perspectives with AL Circle at the recent IBAAS conference. He spoke about the evolution of the Updated Improved Low Temperature Digestion (UILTD) process and how it can enhance efficiency, reduce costs, and support sustainability in alumina refining.

AL Circle: What motivated you to develop and refine the Improved Low Temperature Digestion (ILTD) Process into the Updated ILTD (UILTD) version, and what key challenges in conventional Bayer process operations were you aiming to solve?

Gyorgy Banvolgyi: The key issues with the Conventional Bayer process are as follow:

The Improved Low Temperature Digestion (ILTD) Process is intended to eliminate the drawbacks of the CLTD by the separation of the dissolution reaction of gibbsite from the crystallisation of dissolved reactive silica as DSP. The two different reactors are optimized as per the requirements of the individual reactions. The ILTD Process makes possible to implement a process that would result in about 20 per cent savings in the material and energy (M&E) costs. The bauxite residue by-product of the ILTD Process would contain marginal amount of chemically combined Na2O therefore its further use is certainly a realistic target. The crystallised DSP would be a novel by-product of the ILTD Process. In an earlier paper of mine options were published for the use of DSP by-product, among others, sintering - leaching of DSP though no calculation for the economic viability was presented.

What motivated me to develop and refine the ILTD Process was to demonstrate that the economic viability of the ILTD Process could be further improved. This updated process would contain a unit operation where the DSP by-product is submitted to a sintering-leaching unit within the alumina refinery. It might be worthwhile to mention that the sintering-leaching unit has not been used in the Bayer alumina refineries. The sodium aluminate solution obtained could be readily used in the Bayer process and the dicalcium silicate (belite) by-product is welcome in manufacturing of various types of cements. Therefore implementation of the UILTD Process would be a significant step towards a waste-free process.

AL Circle: Your paper demonstrates a significant reduction in production cost and payback periods of less than three years for Indian alumina refineries. How do you see the UILTD Process contributing to both economic competitiveness and environmental sustainability in the alumina industry?

Gyorgy Banvolgyi: The economic calculations for the UILTD Proces resulted in a reduction of the material and energy (M&E) cost of up to 25 per cent and a payback period of time between 2 and 3 years was arrived at. In our case the material and energy consumption calculations are more accurate than the estimation of CAPEX (Capital Expenditure). During the estimation of CAPEX the results of an earlier Concept Study for an alumina refinery in Latin America were adjusted by internationally accepted inflation rates. In the said Concept Study some principal equipment were anticipated to be purchased from Western Europe. It is widely accepted that the investment costs in India would be significantly less than in the Concept Study. Therefore the investment costs and the payback period of times in India would probably be more favourable than it is indicated in the Case Study in the conference paper. However, making more detailed calculations are beyond the scope of a conference paper.

I firmly believe that implementation of the UILTD Process significantly increases the economic competitiveness and the environmental sustainablity of the alumina industry. The quality of the bauxite feedstocks used in the conference paper are close to what is experienced in the alumina refineries in the Eastern part of India. Paradoxically if the quality of the bauxite feedstock was worse (e.g. higher reactive silica content in bauxite) the economic viability of the UILTD Process would be more favourable.

AL Circle: How do you envision the adoption of the UILTD Process evolving—particularly in regions like India and Australia that have high-silica gibbsitic bauxites—and what further research or collaborations do you believe are essential to accelerate its industrial implementation? Can you name some alumina refineries that have absorbed this process? (Maybe in India or even from around the world)

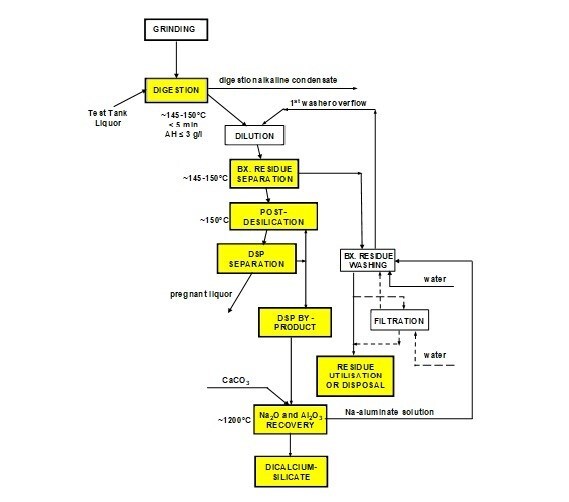

Gyorgy Banvolgyi: Please find here a block flow diagram focusing on the UILTD Process. Those unit operations and by-products that are different from the Conventional Bayer Process are highlighted in yellow.

Sumitomo in Japan implemented in 1993 an improved process that is largely similar to the ILTD. A pressure decanter was part of the process implemented by Sumitomo. Their solution operated for about 7 years. Sumitomo process showed about 50 per cent savings in NaOH consumption though the liquor productivity was significantly less than the benchmark figures. Nevertheless Sumitomo solution can reasonably be considered as a proof of concept for the ILTD Process as well. The pressure decantation technology was put into commercial scale operation in the Kaiser’s Gramercy alumina refinery in USA in 2001 and has been in operation since that time. This effective bauxite separation unit, i.e. the pressure decanter has been in operation for several years in 6 alumina refineries in India, USA, Japan and Australia, in most cases as part of the so-called double digestion technology. The continuous pressure filtration was implemented for filtration of beneficiated (washed) bauxite in Alunorte, Brazil, and for bauxite residue in Indonesia. In other industries the continuous pressure filtration is in commercial scale operation up to temperatures of 160 oC. The sintering-leaching process technology has been in operation for several decades in Russia and China for processing low quality bauxites, bauxite residues with high DSP content and also for nepheline in 12 alumina refineries. The seeded pressure desilication is part of the sintering-leaching technology.

As shown, each of the 5 modified unit operations that are novel in the UILTD Process have been (some were) in commercial scale operation. However, the UILTD Process as a whole has not been implemented as yet. Since the deviations from the CLTD are relatively complex, it is recommended that the UILTD Process be implemented at first in pilot scale. By this way it can be demonstrated that the UILTD Process is feasible and operable. The economy of the UILTD can be checked by a Pre-investment Study (e.g. a Concept Study), it would require moderate amount of financing and can be elaborated in short time, probably in 3-4 months.

Further research or collaborations that are believed to accelerate the industrial implementation:

AL Circle: You mentioned the UILTD Process aligns with six UN Sustainable Development Goals. Could you share which specific SDGs are most impacted and how this process supports the aluminium industry’s global sustainability agenda?

Gyorgy Banvolgyi: The UILTD Process has rightfully been listed to fit to SDGs: 9, 12,15

The UILTD Process has potentially several more implications to the Bayer process than just the residue with very favourable composition. Therefore, it is deemed that the Updated ILTD Process should be and could be included in the following list of SDGs: 7, 13, 17.

The UILTD Process once it is implemented in commercial scale would provide, among others

These benefits relate to processing of good quality bauxite feedstocks in Eastern India. However the benefits would be greater if low quality bauxites or even aluminous laterites comprised the feedstock of the alumina refinery.

Gibbsitic (mainly lateritic) bauxites comprise about 90 per cent of the bauxite resources of the World. The alumina refineries with the lowest procuction cost are based on good quality bauxites, high in soluble alumina, low in reactive silica. However there are several countries where the very good quality bauxites are being depleted and/or the companies face with various difficulties with opening new mines. Therefore they face painful decision: either to reduce their production level, to close some refineries, or to accept lower quaility feedstock that can be processed by the Conventional Bayer Process with higher production costs. It has been proven by a Case Study that using UILTD Process would dramatically increase the amount of bauxite resources and decrease the production costs.