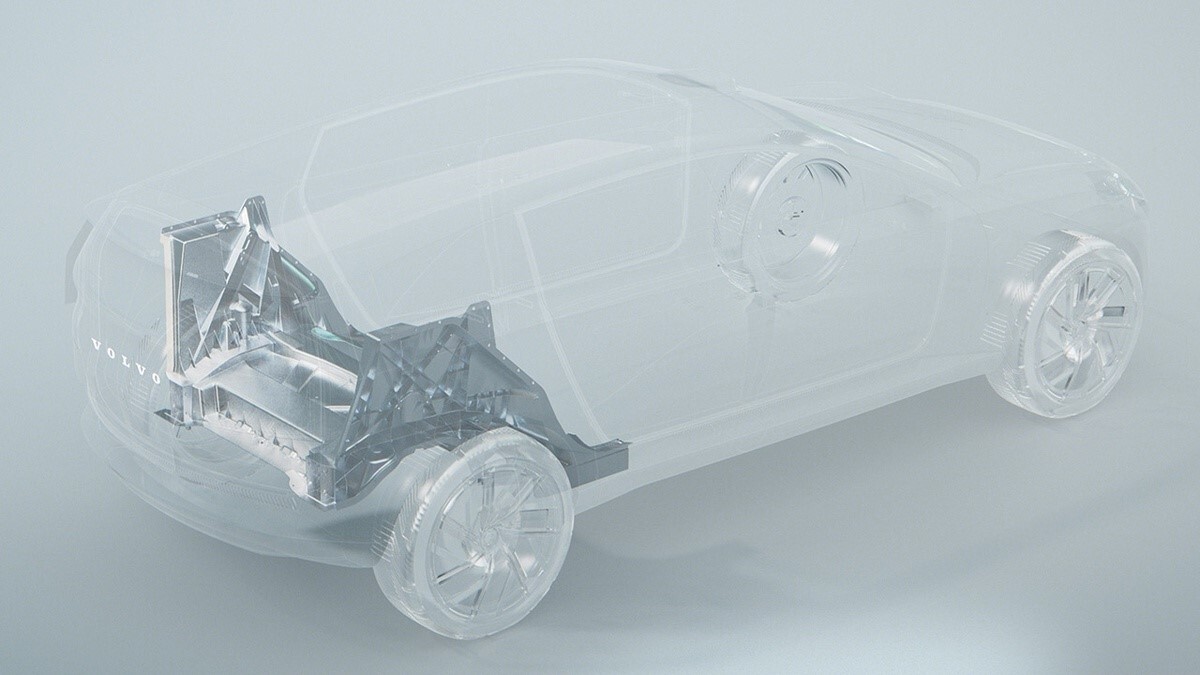

Volvo is poised to inaugurate an unconventional era of production innovation slated to commence in 2026 at its illustrious Torslanda plant in Sweden. This ambitious endeavour is set to unfold alongside the implementation of the SPA3 platform, heralding the third iteration of Volvo's cutting-edge vehicle technology tailored explicitly for electric mobility solutions.

At the heart of this transformative venture lies the ingenious mega-casting technique, a method pioneered by visionaries at Tesla and under consideration by industry stalwart Toyota. This avant-garde approach entails the creation of expansive singular vehicle components through the precision of die-cast moulding, where molten metal is artfully poured into the desired shapes. For instance, envisage the entire rear floor section of forthcoming models materialising as a solitary aluminium masterpiece, supplanting approximately a hundred erstwhile components. The ramifications are profound: a staggering 50% reduction in weight and an impressive 84% decrease in welded joints, underscoring Volvo's unwavering commitment to engineering excellence and sustainability.

Erik Severinson, Volvo's venerable head of strategy and programme management, articulates the brand's forward-looking trajectory with utmost clarity: "By 2030, we have pledged full electrification, necessitating a comprehensive overhaul of our product spectrum to incorporate electric alternatives for discerning patrons." Yet, the veil of mystery shrouds the precise models primed to inaugurate this epochal platform shift.

Amidst fervent speculation, the EX60 emerges as a prime contender for the SPA3 mantle, potentially augmenting Volvo's esteemed electric SUV repertoire with a long-awaited counterpart to the ubiquitous XC60. Anticipated to grace the market by 2025, the EX60 embodies Volvo's unwavering resolve to propel electric mobility into uncharted realms of sophistication and sustainability.

Initiating this paradigm shift, Volvo opts for pristine pressed aluminium, ensuring stringent adherence to quality benchmarks. However, the allure of recycled metal beckons on the horizon, hinting at a future where sustainability reigns supreme, poised to further enhance ecological stewardship.

As the colossal mega-casting apparatus whirs into action, boasting the capability to craft a singular rear tray in a mere 120 seconds, Volvo charts a course towards unprecedented efficiency, with the potential to churn out an impressive 60 cars per hour. Beyond Torslanda's hallowed halls, this pioneering technique is slated for deployment at Volvo's nascent Slovakian facility, with tantalising prospects for global dissemination across its expansive manufacturing network.

If you wish to learn more about the international aluminium market, have a look at AL Circle’s special report Global Aluminium Industry Key Trends to 2030.

Responses