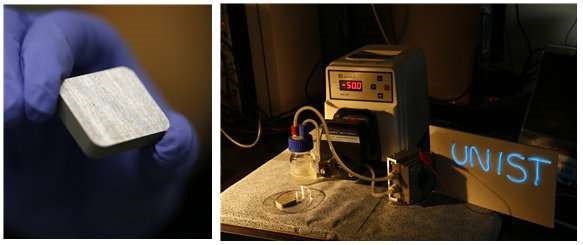

Ulsan National Institute of Science and Technology (UNIST), South Korea has developed an electric vehicle (EV) battery technology that is more energy-efficient than gasoline-powered engines. The new technology allows replacement of battery packs instead of re-charging and can troubleshoot slow charging problem with the existing EV battery technology. It also provides lightweight, high-energy density power sources with the use of aluminium.

Professor Jaephil Cho and his research team led the research in the School of Energy and Chemical Engineering at UNIST. Their findings have been published in an academic journal, Nature Communications on September 13, 2018.

The new type of aluminium-air flow battery for (EVs) developed through the research outperforms existing lithium-ion batteries in terms of energy density, cost, life cycle and safety.

The USP of the Aluminum-air batteries is that they are primary cells and cannot be recharged via conventional means. When applied to EVs, it will produce electricity by simply replacing the aluminium plate and electrolyte. If we compare the energy density of gasoline and aluminium of the same weight, aluminium is superior.

"Gasoline has an energy density of 1,700 Wh/kg, while an aluminium-air flow battery exhibits much higher energy densities of 2,500 Wh/kg with its replaceable electrolyte and aluminium," says Professor Cho. "This means, with 1kg of aluminium, we can build a battery that enables an electric car to run up to 700km."

Metal-air batteries, especially aluminium-air batteries, have shown much potential as the next-generation battery due to their higher energy density. Aluminium batteries are lighter, cheaper, and have a greater capacity than a traditional LIB.

Aluminum-air batteries have the issue of high anode cost and byproduct removal when using traditional electrolytes creating hurdle in its commercial usage. Professor Cho has solved this issue by developing a flow-based aluminium-air battery to alleviate the side reactions in the cell.

The discharge capacity of aluminium-air flow battery increased 17 times, as compared to the conventional aluminium air batteries. The research team expects their aluminium-air flow battery system to help bring more EVs on the road with greater range and substantially less weight, because of their longevity and energy density.

Responses